Determinants of Employee use of Personal Protective Equipment, the Case of Spedag Interfreight Uganda Limited, Kampala

Mildred Ayikoru, Christopher Ddamulira, David R Mutekanga*

School of Graduate Studies, Bugema University, Kampala, Uganda

*Corresponding Author: David R Mutekanga, School of Graduate Studies, Bugema University, Kampala, Uganda

Received: 15 July 2019; Accepted: 22 August 2019; Published: 20 September 2019

Article Information

Citation: Mildred Ayikoru, Christopher Ddamulira, David R Mutekanga. Determinants of Employee use of Personal Protective Equipment, the Case of Spedag Interfreight Uganda Limited, Kampala. Journal of Environmental Science and Public Health 3 (2019): 419-434.

View / Download Pdf Share at FacebookAbstract

In organizations where neglect of safety gears is common, there are high risks of work-related accidents which can be catastrophic. It is against this backdrop that this study was conducted to assess the determinants of use of personal protective equipment (PPE) at the global interfreight clearance agency SPEDAG based at their premises in Kampala, Uganda. Specifically the study was to establish the level of utilization and the determinants for use of such PPE. The study collected quantitative data using questionnaires from a random sample and qualitative data from purposively selected members of top management (Key informants). The results show a relatively high level (70.1%) use of PPEs, a high positive attitude (95%) towards PPE use and a high (95%) availability of guidelines or policies regarding use of PPEs. The results show that the use of the PPE is taken as pertinent and necessary among the employees. These results were confirmed by the qualitative results from the key informants. The authors concluded that continuous sensitization and sustained availability of guidelines and policies must be strongly supported to maximize use of PPEs. The major recommendation is that policy makers in consultation with work safety practitioners should design policies that are sensitive to the perceptions of the users for effective improved use of PPE.

Keywords

<p>Occupational Safety, Personal Protection Equipment, Environment Health</p>

Article Details

1. Introduction

The purpose of personal protective equipment (PPE) is to reduce employee exposure to hazards when engineering and administrative controls are not feasible or effective to reduce these risks to acceptable levels of 0% work place injury [1]. PPE does not eliminate the hazard at the source and non use may result in employees being exposed to accidents and illness if not well used. Any item of PPE imposes a barrier between the user and the potential hazardous working environment [1].

2. Literature Review

It has been established that the hierarchy of hazard controls provides a policy framework which ranks the types of hazard controls in terms of absolute risk reduction, at the top of the hierarchy are elimination and substitution, which remove the hazard entirely or replace the hazard with a safer alternative [2]. PPE is the last line of defense in preventing workplace injuries and ill health. If workers don't understand why they need to wear PPE or don’t have any say in choosing it, they are more likely to refuse to use it than if they are properly trained and involved. According to the US Government [3], Personal protective equipment (PPE) includes protective clothing, helmets, goggles, or other garments and equipment designed to protect the wearer’s body from injury or infection. It further reports that the hazards addressed by protective equipment include physical, electrical, heat, chemicals, biohazards, and airborne particulate matter. Protective equipment may be worn for job-related occupational safety and health purposes, as well as for sports and other recreational activities.

Many scholars have discussed various compelling factors leading to the use of personal protective equipment [4, 5, 6]. It has been reported [4] that the contributing factors were categorized into three: Individual factors such as knowledge, attitude towards the use of PPE, perception of risk and demographics; Environmental/Economic factors such as availability and accessibility; and Organizational factors such as management/administrative measures, guidelines and policies, expectations and feedbacks, trainings and education programs. The Institute of Medicine further reported that most refusals and or failures stem from poor management, communication and training [4, 5, 6]. A researcher [2] noted how amazingly easy it is to put on a pair of gloves and yet workers have a difficult time doing so. Non-use of PPE is an area that requires little effort to improve. A pair of qualified boots is more than enough to reduce the chance of a foot related injury. It does not take much effort to wear the appropriate PPE however, only 64% workers globally on average, constantly use the correct PPE [3]. As a result, approximately 65 million dollars are spent on related injuries in roadway institutions in the United States of America alone [7].

The rate of use of PPE is reported to be very low in Africa [8]. In Namibia, for example, only 10% of industries were found to be using of PPE, most industries were not using PPE as stipulated in the Occupational Health Safety Legislation [9]. In Kahama District of Tanzania, it was established that most (90%) of the healthcare workers had experienced work place injuries which resulted from non-use of PPE. 81% of the workers stated that there was no existence of guidelines and protocols in regards to how to use PPE while performing their duties, and 26% of the staff were not reporting cases hence not identifying the issues [10].

Uganda has been reported to have a high rate (60%) of non-use of all the necessary PPE hence increasing the risk of biological and non-biological hazards in government and private owned hospitals [11]. At SPEDAG Interfreight Uganda, the rate of use of PPE is 75%, according to its Annual report of 2018 [12]. This study focused on the use of PPE at SPEDAG Interfreight Uganda limited, which is a leading provider of end to end supply chain management with offices in Kampala Uganda and branches all over Uganda. They specialize in supply chain management, consolidation Services, Distribution Logistics, Project Logistics, Warehousing, Airfreight, Transports, Sea freight Overland and comprehensive Logistics. They are certified by NEMKO for; ISO: 9001 (Quality), ISO: 14001 (Environment) and OHSAS: 18001 (Occupational health and safety). Despite all the administrative measures and emphasis made for staff to make good use of the PPE at SPEDAG, there was still poor response from most of the staff, accounting for a disproportionately large percentage of all work-related injuries, accidents, near misses [13].

3. Rationale

The use of personal protective equipment is of significance in preventing not only workplace injuries, but also ill health and its related consequences that can be fatal [3]. In SPEDAG Interfreight however, evidence reveals that non-use of the PPEs is among 29.1% of the staff working in warehouses with unknown levels among the rest of the employees [13]. Efforts by the management team has been through ensuring availability of PPE and giving awards to the constant users alongside trainings but the use of PPE remains far from satisfactory. This is because as of the second quarter of the year 2018, there were 14% cases of injuries, 17% security health issues, 12% incidents and 1 accident that led to the loss of an individual’s foot [12]. While understanding the factors for non-use is pertinent for coming up with appropriate strategies, studies to this effect within SPEDAG Interfreight have not been comprehensive. This study was thus set to establish the determinants of use of personal protective equipment at SPEDAG Interfreight Uganda Limited as to recommend appropriate remedies.

4. Objective of the study

The general objective of the study was to assess the determinants of use of personal protective equipment at SPEDAG Interfreight Uganda Limited, which would contribute to developing measures of how to ensure 100% compliance and 0% workplace injuries. The specific objectives of the study were:

- To establish the level of utilization of PPE at SPEDAG Interfreight.

- To assess the individual factors associated with use of PPE at SPEDAG Interfreight.

- To assess the organizational factors associated with use of PPE at SPEDAG Interfreight.

5. Methods of Data Collection

This work adopted both qualitative and quantitative research approaches. The specific research design of the study was descriptive cross sectional research design. The descriptive research design helped in describing the phenomenon. The study was cross sectional because it was carried out at one point in time from various sample elements in the population.

5.1 Locale of the study

It was carried out at SPEDAG Interfreight Uganda Limited, Nakawa Division, Kampala district, Uganda. SPEDAG is a leading provider of end to end supply chain management with offices in Kampala and branches all over Uganda. The study was conducted in 4 offices of Kampala namely Nakawa, Luzira, Namanve and Butto. The company specializes in supply chain management, consolidation Services, Distribution Logistics, Project Logistics, Warehousing, Airfreight, Transports, Sea freight Overland and comprehensive Logistics.

5.2 Study population and sample size

The study population (230) was the employees of SPEDAG Interfreight Uganda Limited, from four branches: Nakawa, Luzira, Butto and Namanve offices. These were composed of both male and female respondents. The unit of analysis was the employees of the company. The sample size of the study was 140 full time staff members as respondents derived using the [14] formula for obtaining a proportionate sample allocation, taken to be the appropriate sample size to answer whether there is a significant influence from a total of 230 (Table 1).

|

Category |

Population of the category |

Sample of the category |

|

Top management |

10 |

6 |

|

Full time staff members |

160 |

97 |

|

Support staff |

60 |

37 |

|

Total |

230 |

140 |

Source: Human Resource Department, SPEDAG Interfreight Uganda Limited and the Sample Size Calculations Formular [12, 14].

Table 1: Population and Sample Size of the study.

5.3 Instruments

Two methods were used to collect the data: that is the survey among the workers and specially selected Key Informant Interview (KII). The instruments used were the questionnaire to collect the general data and the Key Informant Interview Guide to collect specific data. Triangulation of the two study instruments was employed where analyzed data was thematically incorporated within the corresponding qualitative and quantitative data to draw clear conclusions using related responses as one theme basing on the findings. Corresponding information of short interlinked phases with key questions was used. Quantitative data was analyzed using statistical packages for social sciences (SPSS) version 20.0 for windows. Both descriptive and inferential statistics were processed. Qualitative data was organized into coherent categories to summarize the data, and then analyzed by the use of coherent analysis for find meaningful information.

6. Results And Discussion

6.1 Demographic characteristics of the employees at spedag

The demographic characteristics considered included sex, formal education level, age and marital status of the employees. The descriptive results in this regard are presented in Table 2 below.

6.1.1 Sex: The results (Table 2) show that more than a half of the employees at SPEDAG Interfreight (58.4%) were males. This could be explained by the fact that most of the tasks that SPEDAG Interfreight handles are high risky tasks and that men observe the use of PPE. These results well compare to the earlier findings in California [15] which concluded that men are more observed using PPE compared to the women. The results are however not in line with those by an earlier researcher reporting [16] that fear of harm and injuries among women, makes females better users of PPE. One of the key informants in this case said:

“As for this company most of the work done is for the men. Majority females are in offices with few of them in the operations” (KI2, 2018).

|

Demographic characteristic |

Frequency (N=137) |

Percentage (%) |

|

Sex |

||

|

Male |

80 |

58.4 |

|

Female |

57 |

41.6 |

|

Highest Education Level |

||

|

None |

2 |

1.5 |

|

Primary |

3 |

2.2 |

|

High school |

46 |

33.6 |

|

Diploma |

23 |

16.8 |

|

Degree |

60 |

43.8 |

|

Others (Masters, professional certificate) |

3 |

2.2 |

|

Age in years |

||

|

Below 25 |

35 |

25.5 |

|

25 to 34 |

77 |

56.2 |

|

35 to 44 |

20 |

14.6 |

|

45 and above |

5 |

3.6 |

|

Marital Status |

||

|

Married |

51 |

37.2 |

|

Not married |

80 |

58.4 |

|

Divorced |

4 |

2.9 |

|

Cohabiting |

2 |

1.5 |

Table 2: Individual factors of employees at SPEDAG Interfreight.

6.1.2 Highest education level: On education, most employees at SPEDAG Interfreight had studied up to a degree level (43.8%) as the highest level (Table 2). This could be attributed to the fact that the tasks that SPEDAG Interfreight requires professional techniques which are only possible for people with a good level of education. These results are not in line with those found earlier [17] that 59.8% had secondary education and 15% were found to be illiterate. In this regard one of the key informants said that:

“We mostly employ workers who are educated with at least a degree. I must say that majority workers in this organization are educated up to say a reasonable level. Because we even have those ones of degree diploma and others. But generally workers are educated.” (KI3, 2018).

6.1.3 Age of Employees: Most of the SPEDAG Interfreight employees (56.2%) are youth aged 25 to 34 years. This could be mainly because the operations of SPEDAG Interfreight require to be done by energetic youths. These results compare well with those earlier reported [6] that the young pickers easily adopted the use of PPE as compared to the elderly pickers and they concluded that the PPE use was influenced by age. They however differ from other results [18] which reported that among the ages 43-56 year olds wearing PPE significantly impaired the elderly than the young. This was supported by responses from the key informants, who said that:

“I think it is the case here that most of the work done at SPEDAG Interfreight especially requires someone who is energetic. That’s why you see some energetic youths neither too old nor too young.” (KI2, 2018).

6.1.4 Marital status: The majority of the respondents at SPEDAG are not married (58.4%). This may be due to the youthful employees that are recruited to fit the nature of operations at the organization. These results differ from those found by [19] a researcher in Mirchaiya, Nepal who reported that factory workers were mostly married people and they use PPE more than the unmarried.

6.2 Level of utilization of ppe at spedag interfreight

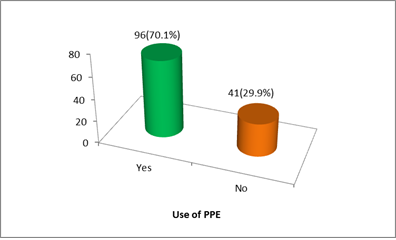

In order to establish the level of utilization of PPE at SPEDAG among the employees, it was found that most respondents (70.1%) use PPE at all times while at work (Figure 1 below).

Figure 1: Level of PPE use.

The above results are further supported by responses from the key interviewees, who said that:

“In this organization, at least everyone tries to effectively use PPEs especially those who work in the yard.” (KI1,2018).“Every worker here knows the importance of using PPEs thus everyone uses PPEs effectively. Moreover it is a mandatory to use PPEs.” (KI2, 2018).

This level of use of the PPEs in SPEDAG is higher than that reported at global level by the World Health Organization [20]. and that sharp injuries remain the commonest cause of exposure to blood-borne diseases for health care workers due to non-compliance to use of PPE remain a challenge for health professionals in the workplace globally.

6.3 Individual factors associated with use of ppe at spedag

The study further established the individual factors associated with use of PPE at SPEDAG. The factors studied included attitude towards PPE use, knowledge of use of PPE and peer influence. The results in Table 3 below show high attitude towards use of PPE (90.5%), high knowledge about PPE (89.1%) and high peer support (89.8%) towards colleagues to use PPE.

|

Individual factor |

Frequency (N=137) |

Percentage (%) |

|

Recommend use of PPE to a friend (attitude) |

||

|

Yes |

124 |

90.5 |

|

No |

13 |

9.5 |

|

Knowledge (Illustrated to on how to use PPE) |

||

|

Yes |

122 |

89.1 |

|

No |

15 |

10.9 |

|

Colleagues encourage another if forget to use PPE |

||

|

Yes |

123 |

89.8 |

|

No |

14 |

10.2 |

Table 3: Description of the individual factors associated with use of PPE.

6.3.1 Individual attitude: There is high individual attitude towards using PPE in SPEDAG, however some other studies report poor attitude [21]. This may be related to the individual national differences and how the PPE is being introduced to the workers.

6.3.2 Knowledge: This high knowledge about PPE at SPEDAG contributes to the high adherence to PPE. This is further supported by the other studies [22] which showed that insufficient safety training between the employees is the general root cause of accidents in the construction sites because they did not have the knowledge, education and skills to recognize potential hazards at site.

6.3.3 Peer influence: The results in Table 3 above further show that most employees at SPEDAG are encouraged by their colleagues in case they forget to put on the personal protective gadgets (89.8%). This could be attributed to the risky activities normally undertaken and no one can work with the other when he or she is not wearing the protective equipment. This is despite the report by the World Health Organization [20] that work relationships are potential stressors among the workers in the organizations and particularly lack of staff support which may affect the positive peer influence.

6.4 Organizational factors associated with use of PPE at SPEDAG

This study also identified the organizational factors associated with use of PPE at SPEDAG. These factors included availability of PPE, accessibility of PPE, guidelines / policies regarding use of PPE, training on use and importance of PPE and the economic situation of the organization. Table 4 below shows the descriptive results.

|

Organizational factors |

Frequency (N=153) |

Percentage (%) |

|

|

Whether PPEs are enough for the members of staff |

Yes |

117 |

85.4 |

|

No |

20 |

14.6 |

|

|

Whether the PPEs are easily accessed |

Yes |

119 |

86.9 |

|

No |

18 |

13.1 |

|

|

Whether the individual respondents have ever |

Yes |

110 |

80.3 |

|

No |

27 |

19.7 |

|

|

Whether individuals have ever received |

Yes |

109 |

79.6 |

|

No |

28 |

20.4 |

|

|

Whether the organization procures |

Yes |

124 |

90.5 |

|

No |

13 |

9.5 |

|

Table 4: Organizational factors associated with use of personal protective equipment at SPEDAG Interfreight Uganda Limited.

6.4.1 Availability of PPE: The results show that most of the respondents (85.4%) receive enough PPEs from the organization. This could be attributed to the significance the organization places on the safety of each and every employee. An earlier study [23] confirms that lack of adequate equipment and tools for protection in the health facilities contributed to non-compliance to use of PPE among the workers. However, other studies NIOSH [24] reported that workplace hazardous drug exposure is a persistent problem among health care workers and that though PPE was highly availed in all workplaces and were in abundance, the compliance rate was still poor.

6.4.2 Accessibility of PPE: The results in Table 4 show that despite availability of PPE only 89.6% access the equipment. This could be because some of the employees rarely reach the areas where the risky operations are done. These results are quite similar to those reported earlier [25] where the use of PPE for nursing professionals in primary health care facilities was very low despite availability of the PPE. The workers, however, reported poor access to the available PPE.

6.4.3 Guidelines/policies regarding use of PPE: This study established that there are guidelines and policies regarding the use of PPE at SPEDAG. That these guidelines and policies are made known to the employees and most of them know about them (80.3%). The availability of these guidelines and policies is in compliance with the Occupational, Safety and Health Act [3].

6.4.4 Trainings on use of PPE and there importance: Other results in relation to organizational factors show as per presentation in Table 5 that majority employees at SPEDAG Interfreight Uganda Limited had ever received training on the awareness and use of PPE (79.6%). The results however show that some members had not received training on the awareness and use of PPE an indication that there are areas for management to make improvements. These findings are quite comparable to those of another researcher [26], that training employees on potential of accidents, how to prevent accidents and potential hazards involved in their jobs, helps to enhance the use of PPE.

6.4.5 Economic situation of the organization: The majority (90.5%) of the respondents also reported that the organization procures sufficient and right PPEs. This means that the economic situation within the organization is good enough to promote the use of PPEs. The results are quite comparable to those earlier reported [27] that noncompliance is directly related also to economic conditions, but it is essential that workers wear PPE whenever it is required.

6.5 The relationship between individual and organizational factors (bivariate)

To establish the relationship between individual and organizational factors associated with the use of PPE at SPEDAG Interfreight, the Pearson Chi square analysis at bivariate analysis level was undertaken. Cross tabulations alongside Crude Odds Ratios (COR) were also processed at bivariate analysis level. The results were presented in Tables 5 and 6 respectively below.

|

Individual factors |

PPE use |

P-Value |

||||

|

Yes N (%) |

No N (%) |

χ2 |

Df |

|||

|

Sex |

Male |

58 (72.5) |

22 (27.5) |

0.540 |

1 |

0.462 |

|

Female |

38 (66.7) |

19 (33.3) |

||||

|

Education level |

Up to High school |

39 (76.5) |

12 (23.5) |

1.586 |

1 |

0.208 |

|

Tertiary |

57 (66.3) |

29 (33.7) |

||||

|

Age in years |

Below 35 |

79 (70.5) |

33 (29.5) |

0.063 |

1 |

0.802 |

|

35 and above |

17 (68.0) |

8 (32.0) |

||||

|

Marital status |

Married |

35 (66.0) |

18 (34.0) |

0.671 |

1 |

0.413 |

|

Unmarried |

61 (72.6) |

23 (27.4) |

||||

|

Individual attitude |

Positive |

91 (73.4) |

33 (26.6) |

6.844 |

1 |

0.009** |

|

Negative |

5 (38.5) |

8 (61.5) |

||||

|

Knowledge of use of PPE |

Yes |

90 (73.8) |

32 (26.2) |

7.264 |

1 |

0.007** |

|

No |

6 (40.0) |

9 (60.0) |

||||

|

Peer influence |

Yes |

96 (78.0) |

27 (22.0) |

36.512 |

1 |

0.000** |

|

No |

0 (0.0) |

14 (100.0) |

||||

**Significant at 5% level

Table 5: Bivariate results for the individual factors associated with use of personal protective equipment.

Table 5 above shows that the following individual factors: sex, formal education level, age in years and marital status are not statistically associated with use of personal protective equipment at bivariate analysis level. The Table (5) however shows that individual attitude, knowledge of use of PPE, and peer influence are significantly associated with use of personal protective equipment at bivariate analysis level.

|

Organizational factors |

Prevalence of PPE use |

P-Value |

||||

|

Yes N (%) |

No N (%) |

χ2 |

df |

|||

|

Availability of PPE |

Yes |

86 (73.5) |

31 (26.5) |

4.500 |

1 |

0.034** |

|

No |

10 (50.0) |

10 (50.0) |

||||

|

Accessibility of PPE |

Yes |

90 (75.6) |

29 (24.4) |

13.338 |

1 |

0.000** |

|

No |

6 (33.3) |

12 (66.7) |

||||

|

Guidelines/policies regarding use of PPE |

Yes |

88 (80.0) |

22 (20.0) |

26.228 |

1 |

0.000** |

|

No |

8 (29.6) |

19 (70.4) |

||||

|

Trainings on use of PPE and there importance. |

Yes |

83 (76.1) |

26 (23.9) |

9.382 |

1 |

0.002** |

|

No |

13 (46.4) |

15 (53.6) |

||||

|

Economic situation of the organization |

Yes |

95 (76.6) |

29 (23.4) |

26.652 |

1 |

0.000** |

|

No |

1 (7.7) |

12 (92.3) |

||||

**Significant at 5% level

Table 6: Organizational factors associated with use of personal protective equipment at SPEDAG Interfreight Uganda Limited.

Table 6 above shows that at bivariate analysis level, the availability of PPEs, accessibility of PPEs and availability of guidelines or policies regarding use of PPEs are the organizational factors statistically associated with use of personal protective equipment at SPEDAG Interfreight Uganda Limited. The use of personal protective equipment is highest among employees that reported availability of PPE (73.5%), accessibility of PPEs (75.6%) and availability of guidelines or policies regarding use of PPEs (80.0%). The results further show that the use of personal protective equipment is highest among employees that had received training on their use and their importance (76.1%), and also those that reported the economic situation of the organization as good (76.6%).

6.6 The relationship of all factors associated with use of PPE using the multivariate analysis

To establish the level of significance of factors, all the variables both individual and organizational with all cell counts equal to or above 5 so as to uphold the asymptotic assumptions were subjected to multivariate analysis using the binary logistic regression. In addition, the Adjusted Odds Ratios (AOR) for each of the factors considered was processed at a 95% confidence level. The results are presented in Table 7.

|

Individual factors |

Prevalence of PPE use |

COR (95%CI) |

AOR (95%CI) |

|||

|

Yes N (%) |

No N (%) |

|||||

|

Individual attitude |

||||||

|

Positive |

91 (73.4) |

33 (26.6) |

4.412 (1.347-14.448) |

4.118 (1.063-15.955)* |

||

|

Negative |

5 (38.5) |

8 (61.5) |

||||

|

Knowledge of use of PPE |

||||||

|

Yes |

90 (73.8) |

32 (26.2) |

4.219 (1.392-12.788) |

2.013 (0.401-10.094) |

||

|

No |

6 (40.0) |

9 (60.0) |

||||

|

Organizational factors |

||||||

|

Availability of PPE |

||||||

|

Yes |

86 (73.5) |

31 (26.5) |

2.774 (1.054-7.303) |

1.710 (0.010-0.130) |

||

|

No |

10 (50.0) |

10 (50.0) |

||||

|

Accessibility of PPE |

||||||

|

Yes |

90 (75.6) |

29 (24.4) |

6.207 (2.138-18.016) |

13.195 (0.714-243.737) |

||

|

No |

6 (33.3) |

12 (66.7) |

||||

|

Yes |

88 (80.0) |

22 (20.0) |

9.500 (3.678-24.540) |

8.354 (2.445-28.546)* |

||

|

No |

8 (29.6) |

19 (70.4) |

||||

|

Trainings on PPE use and importance |

||||||

|

Yes |

83 (76.1) |

26 (23.9) |

3.683 (1.553-8.735) |

0.683 (0.165-2.827) |

||

|

No |

13 (46.4) |

15 (53.6) |

||||

*Significant at 5% level

Table 7: Multivariate results of the factors associated with use of PPE at SPEDAG Interfreight Uganda Limited

6.7 Individual factors influencing use of PPEs

6.7.1 Individual attitude: Table 7 above shows that the individual attitude of the employees towards PPE use is statistically associated with the prevalence of use of the personal protective equipment at bivariate analysis level (COR=4.412;95% CI=1.347-14.448; p=0.009). When subjected to a multivariate analysis, individual attitude of the employees towards PPE use similarly showed a significant association (AOR=4.118; 95%CI=1.063-15.955; p=0.041). This means that employees who demonstrate a positive attitude towards PPE use are 4.118 more likely to use the personal protective equipment than those that demonstrate a negative attitude. These findings are similar to those earlier established [28] that the decision to make use of the PPE was entirely personal and very minimal influence was made by outside parties. However, other researchers [29] have reported that the use of PPE was influenced by knowledge, age and length of employment.

The results in Table 7 on individual attitude are further supported by the key Informants as indicated below:

“In this company most employees perceive use of PPEs as important in their work. This is because they help to reduce injuries in of an accident while at work. For example, take scenario when you step on a sharp item when you are bear footed when working, we expect to deliver results it’s better to avoid by putting on safety gadgets. (KI1, 2018)

6.7.2 Knowledge of use of PPE: The study (Table 7) further shows that knowledge on use of PPE was significantly associated with the use of PPEs (COR=4.219; 95%CI=1.392-12.788; p=0.007). The employees who had knowledge on use of PPEs were 4.219 times more likely to use PPEs than those who had no knowledge on use of PPEs. These results are similar to studies done in 2010 [26] which showed that for efficient compliance to use of PPE, it is important to educate employees on potential of accidents, how to prevent accidents and potential hazards involved in their jobs. They are also similar to reports from the World health Organization [20] that training and education programs play a significant role in enhancement of safety in construction and important to increase safety awareness and change behavior of employees.

One of the key informants concurred with this finding:

“In this company, we expect everyone to know how to use PPEs as we emphasize them from the beginning. Everyone in the company is aware of the importance of using PPEs given the environment and the emphasis we put. (KI2, 2018).

The results when subjected to multivariate analysis show possession of knowledge on use of PPE is not a significant predictor of use of PPEs (AOR=2.013; 95% CI=0.401-10.094; p=0.395). This could be attributed to the fact that having knowledge about use does not necessarily translate into use of the PPEs.

6.8 Organizational factors influencing use of PPEs

6.8.1 Availability of PPE: The results in Table 7 also show that the availability of PPEs was statistically associated with the use of PPEs at bivariate analysis level (COR=2.774; 95%CI=1.054-7.303; p=0.034). The employees who reported availability of PPEs were 2.774 times more likely to use PPEs than those who reported limited availability of PPEs. These results are similar to studies done earlier [30] and reported, that lack of equipment and tools for protection among workers while executing their duties are among the social cultural factors that contributed to non-compliance to use of PPE.

A key informant concurred with this finding:

“The company procures sufficient and relevant PPEs. We provide everyone with PPEs and tell their supervisors to follow up each time before including the newly recruited workers” (KI1, 2018).

When subjected to multivariate analysis however, the results showed an insignificant influence of the availability of PPEs on the use of PPEs (AOR=1.710; 95%CI=1.054-7.303; p=0.121).

6.8.2 Accessibility of PPE: Accessibility of PPEs has a statistically significant effect on the use of PPEs at bivariate analysis level (COR=6.207; 95%CI=2.138-18.016; p=0.083). This relationship was however insignificant at multivariate analysis level (AOR=13.195; 95%CI=0.714-243.737; p=0.083). The employees who reported accessibility of PPEs were however 13.195 times more likely to use PPEs than those who reported limited ease of accessibility. Other researchers [31] do agree when they reported that the compliance rate was poor due factors especially lack of access to the items. These study findings are supported by responses from one of the Key Informants:

The procedures for accessing the PPEs in this organization are easy and the supervisors are always keen to provide the PPEs”, (KI3, 2018).

6.8.3 Guidelines and policies regarding use of PPE: The availability of Guidelines or policies regarding use of PPEs was significantly associated with the prevalence of use of the PPE at bivariate analysis level (COR=9.500; 95% CI=3.678-24.540; p=0.000). This association remains significant when subjected to a multivariate analysis, (AOR=8.354; 95%CI=2.445-28.546; p=0.001). The employees who reported availability of guidelines or policies regarding use of PPEs were 8.354 times more likely to use the PPE than those that did not report availability of guidelines or policies regarding use of PPEs.

These findings were supported by the qualitative responses from one of the key informants:

“In this company, before one is provided with any PPE they are given guidelines on how to use, and the use of PPEs is mandatory in the due places. (KI2, 2018)

These results are supported by other researchers [32, 33], that compliance with safety requirements can help the work to be done both efficiently and safely but procedural instructions are important.

6.8.4 Trainings on PPE use and importance: Trainings on PPE use and importance is statistically associated with the use of personal protective equipment at bivariate analysis level (COR=3.683; 95%CI =1.553-8.735; p=0.002). The employees who reported receipt of trainings on PPE use and importance were 3.683 times more likely to use the PPEs than those that report no availability of guidelines and or policies regarding use of PPEs. However training on PPE use and importance is not statistically associated with use of personal protective equipment when subjected to a multivariate analysis, (AOR=0.683; 95%CI=0.165-2.827; p=0.599).

7. Conclusions and Recommendations

7.1 Conclusion

The use of the Personal Protection Equipment in SPEDAG is taken pertinent with attitude of the employees towards their use and availability of guidelines or policies regarding their use. This implies that there is need for not only continuous sensitization but sustained availability of guidelines or policies to check non-use of PPEs and to achieve 100% use of PPEs. However achieving complete compliance has some challenges [34].

7.2 Recommendations

This study wishes to recommend that institutions need to set up guidelines and policies and ensure that they are known by the employees and are fulfilled. There also need for continuous safety training programs to promote an understanding on the significance of use of PPE. It is also further recommended that organizations like SPEDAG Interfreight should award employees who display full compliance to use of PPE at the right time as required. This will motivate other staff to appreciate and use PPE.

Acknowledgements

The authors wish to thank Bugema University School of Graduate Studies for the support given in the research and write up of this manuscript. They also wish to thank SPEDAG Uganda for allowing their employees and systems to be used in data collection. Their continued support in ensuring complete safety of their employees is highly appreciated.

Conflict of Interest

The authors declare no conflict of interest. The sponsors and supporters had no role in the design, execution, interpretation, or writing of the study.

References

- Kaufman S. What is the Purpose of Personal Protective Equipment (PPE)? The Rat Lab News. Environment health and Safety Office, Emory University, Atlanta Georgia, US (2014).

- Druley K. The Hierarchy of Controls in Safety and Health, National Safety Council, US (2018).

- Department of Labor, Personal Protective Equipment. Occupational Safety and Health Administration, OSHA 3151-12R (2003).

- Hitoshi Honda and Kentaro Iwata. Personal protective equipment and improving compliance among healthcare workers in high-risk settings. Current Opinion in Infectious Diseases 29 (2016): 400-406.

- Bakhsh K, Ahmad N, Tabasum S, et al. Health hazards and adoption of personal protective equipment during cotton harvesting in Pakistan. Science of the Total Environment 598 (2017): 1058-1064.

- Baksh K, Ganpat W, Narine L. Farmers knowledge, attitudes and perceptions of occupational health and safety hazards in Trinidad, West Indies and implications for the Agriculture sector. Journal of Agricultural Extension and Rural Development 7 (2015): 221-228.

- Sheldon Lisa. The Importance of PPE Use. AJN, American Journal of Nursing 119 (2019): 10.

- Nghitanwa EM, Zungu LI. Occupational Health and Safety legislative compliance in the construction sites in Windhoek, Namibia. International Journal of Health 5 (2017): 67-73.

- The Ministry of Labor, Industrial Relations and Employment Creation of Namibia. National policy on Occupational Health and Safety. Windhoek, Namibia (2016).

- Laisser RM, Ng'home JF. Reported incidences and factors associated with percutaneous injuries and splash exposures among healthcare workers in Kahama District, Tanzania. Tanzania Journal of Health Research 19 (2017).

- Ndejjo R, Musinguzi G, Yu X, et al. Occupational health hazards among healthcare workers in Kampala, Uganda. Journal of environmental and public health (2015).

- SPEDAG Uganda Annual Report of 2018. Unpublished Organizational Report. Kampala, Uganda (2018).

- SPEDAG Uganda Annual Report of 2017. Unpublished Organizational Report. Kampala, Uganda (2017).

- Krejcie RV, Morgan DW. Determining sample size for research activities. Educational and psychological measurement 30 (1970): 607-610.

- Schenker MB, Farrar JA, Mitchell DC, et al. Agricultural dust exposure and respiratory symptoms among California farm operators. Journal of occupational and environmental medicine 47 (2005): 1157-1166.

- Izudi J, Ninsiima V, Alege JB. Use of personal protective equipment among building construction workers in Kampala, Uganda. Journal of environmental and public health (2017).

- Eze BI, Okoye O, Aguwa EN. Awareness and Utilization of Welders’ Personal Protective Eye Devices and Associated Factors: Findings and Lessons From a Nigerian Population. Workplace health and safety 63 (2015): 170-178.

- Punakallio A, Lusa S, Luukkonen R. Protective equipment affects balance abilities differently in younger and older firefighters. Aviation, space, and environmental medicine 74 (2003): 1151-1156.

- Sah JP, Shah SK, Yadav DK, et al. Knowledge and practice related to Occupational Hazards among Maruti Cement Factory workers in Mirchaiya, Siraha, Nepal. Microbes and Health 4 (2016): 11-18.

- Fact Sheets 30th November 2017: Protecting Worker’s Health. Down (2017).

- Yuantari MG, Van Gestel CA, Van Straalen NM, et al. Knowledge, attitude, and practice of Indonesian farmers regarding the use of personal protective equipment against pesticide exposure. Environmental monitoring and assessment 187 (2015): 142.

- Toole TM, Carpenter G. Prevention through design: An important aspect of social sustainability. In ICSDC 2011: Integrating Sustainability Practices in the Construction Industry (2012): 187-195.

- Nicholau D, Arnold III WP. Environmental safety including chemical dependency. In Eds.: Miller RD, Lars Eriksson, Lee Fleisher, et al. Miller's Anesthesia. 7th United States, Chuchil Livingstone Elsevier (2010): 3053-3073.

- AHC MEDIA. A new Focus on PPE Compliance: CDC looking at PPE observation and feedback approach. Hospital Infection Control and Prevention 44 (2017).

- Vieira AN, Da Costa Lima DW, Da Silva FT, et al. Use of personal protective equipment for nursing professionals in primary health care. Journal of Nursing UFPE on line-ISSN: 1981-8963 9 (2015): 1376-3183.

- Ghani MK, Abdul Hamid Z, Mohd Zain MZ, et al. Safety in Malaysian Construction: The Challenges and Initiatives. Contruction Research Institute Malaysia (CREAM), CIDB Malaysia (2010).

- Moustaka E, Constantinidis TC. Sources and effects of work-related stress in nursing. Health science journal 4 (2010): 210.

- Carpenter WS, Lee BC, Gunderson PD, et al. Assessment of personal protective equipment use among Midwestern farmers. American journal of industrial medicine 42 (2002): 236-247.

- Hasanah H, Setiawati EP, Apriani L. Knowledge and intention to use personal protective equipment among health care workers to prevent Tuberculosis. Althea Medical Journal 3 (2016): 120-125.

- Kilbourne Chris. PPE Noncompliance: A Serious Threat to Safety and Health (2011).

- He BY, Mendelsohn-Victor K, McCullagh MC, et al. Personal Protective Equipment Use and Hazardous Drug Spills among Ambulatory Oncology Nurses: Results from a Mailed Survey. In Oncology nursing forum NIH Public Access 44 (2017): 60.

- Che Hassan CR, Basha OJ, Wan Hanafi WH. Perception of Building Construction Workers towards Safety, Health and Environment, Journal of Engineering Science and Technology 2 (2007): 271-279.

- Che Hassan CR, Periaiah N, Ismail KI. Workers Behaviour towards Environmental Health and Safety in Road Construction Industries, University of Malaya Malaysia (2010).

- Cascardo, Debra. Compliance Challenges Facing Healthcare Providers in 2016. The Journal of medical practice management: MPM 31 (2016): 276-279.

Impact Factor: * 3.6

Impact Factor: * 3.6 Acceptance Rate: 76.49%

Acceptance Rate: 76.49%  Time to first decision: 10.4 days

Time to first decision: 10.4 days  Time from article received to acceptance: 2-3 weeks

Time from article received to acceptance: 2-3 weeks