Characteristics of New Sourdough using Lactic Acid Bacteria and Wild Yeast

Article Information

Noriko Komatsuzaki1*, Mina Izawa1, Madoka Suzumori1, Shinobu Fujihara1, Jun Shima2

1Department of Human Nutrition, Seitoku University, Chiba, Japan

2Department of Agriculture, Ryukoku University, Shiga, Japan

*Corresponding Author: Noriko Komatsuzaki, Department of Human Nutrition, Seitoku University, 550 Iwase Matsudo, Chiba 271-8555, Japan

Received: 09 January 2019; Accepted: 21 January 2019; Published: 05 February 2019

Citation:

Noriko Komatsuzaki, Mina Izawa, Madoka Suzumori, Shinobu Fujihara, Jun Shima. Characteristics of New Sourdough using Lactic Acid Bacteria and Wild Yeast. Journal of Food Science and Nutrition Research 2 (2019): 001-012.

View / Download Pdf Share at FacebookAbstract

We examined the various effects of lactic acid bacteria (LAB) and yeast on sourdough bread and aimed at the development of a new sourdough bread using wild yeast isolated from fruit and LAB isolated from a traditional Japanese fermented fish (funa-sushi). We made sourdough by using Lactobacillus paracasei NFRI 7415 and baker’s yeast isolated from fruit. Fermentation tests of four types of sourdough were carried out for 4 days: LAB+yeast (28°C), LAB (28°C), LAB and yeast (8°C) and LAB (8°C). The CO2 production and the organic acid and free amino acid contents of the sourdough from LAB and yeast fermented at 28°C were higher than those of the other sourdough. These results indicate that for the new sourdough, the most suitable fermentation period is 3 days and the most suitable temperature is 28°C. Our findings demonstrate that it is possible to develop new sourdough bread using sourdough by the co-fermentation of LAB and wild yeast.

Keywords

Lactobacillus paracasei NFRI 7415, Sourdough, Wild yeast, Sourdough bread, Organic acids

Lactobacillus paracasei NFRI 7415 articles Lactobacillus paracasei NFRI 7415 Research articles Lactobacillus paracasei NFRI 7415 review articles Lactobacillus paracasei NFRI 7415 PubMed articles Lactobacillus paracasei NFRI 7415 PubMed Central articles Lactobacillus paracasei NFRI 7415 2023 articles Lactobacillus paracasei NFRI 7415 2024 articles Lactobacillus paracasei NFRI 7415 Scopus articles Lactobacillus paracasei NFRI 7415 impact factor journals Lactobacillus paracasei NFRI 7415 Scopus journals Lactobacillus paracasei NFRI 7415 PubMed journals Lactobacillus paracasei NFRI 7415 medical journals Lactobacillus paracasei NFRI 7415 free journals Lactobacillus paracasei NFRI 7415 best journals Lactobacillus paracasei NFRI 7415 top journals Lactobacillus paracasei NFRI 7415 free medical journals Lactobacillus paracasei NFRI 7415 famous journals Lactobacillus paracasei NFRI 7415 Google Scholar indexed journals Sourdough articles Sourdough Research articles Sourdough review articles Sourdough PubMed articles Sourdough PubMed Central articles Sourdough 2023 articles Sourdough 2024 articles Sourdough Scopus articles Sourdough impact factor journals Sourdough Scopus journals Sourdough PubMed journals Sourdough medical journals Sourdough free journals Sourdough best journals Sourdough top journals Sourdough free medical journals Sourdough famous journals Sourdough Google Scholar indexed journals Wild yeast articles Wild yeast Research articles Wild yeast review articles Wild yeast PubMed articles Wild yeast PubMed Central articles Wild yeast 2023 articles Wild yeast 2024 articles Wild yeast Scopus articles Wild yeast impact factor journals Wild yeast Scopus journals Wild yeast PubMed journals Wild yeast medical journals Wild yeast free journals Wild yeast best journals Wild yeast top journals Wild yeast free medical journals Wild yeast famous journals Wild yeast Google Scholar indexed journals Organic acids articles Organic acids Research articles Organic acids review articles Organic acids PubMed articles Organic acids PubMed Central articles Organic acids 2023 articles Organic acids 2024 articles Organic acids Scopus articles Organic acids impact factor journals Organic acids Scopus journals Organic acids PubMed journals Organic acids medical journals Organic acids free journals Organic acids best journals Organic acids top journals Organic acids free medical journals Organic acids famous journals Organic acids Google Scholar indexed journals Sourdough bread articles Sourdough bread Research articles Sourdough bread review articles Sourdough bread PubMed articles Sourdough bread PubMed Central articles Sourdough bread 2023 articles Sourdough bread 2024 articles Sourdough bread Scopus articles Sourdough bread impact factor journals Sourdough bread Scopus journals Sourdough bread PubMed journals Sourdough bread medical journals Sourdough bread free journals Sourdough bread best journals Sourdough bread top journals Sourdough bread free medical journals Sourdough bread famous journals Sourdough bread Google Scholar indexed journals lactic acid bacteria articles lactic acid bacteria Research articles lactic acid bacteria review articles lactic acid bacteria PubMed articles lactic acid bacteria PubMed Central articles lactic acid bacteria 2023 articles lactic acid bacteria 2024 articles lactic acid bacteria Scopus articles lactic acid bacteria impact factor journals lactic acid bacteria Scopus journals lactic acid bacteria PubMed journals lactic acid bacteria medical journals lactic acid bacteria free journals lactic acid bacteria best journals lactic acid bacteria top journals lactic acid bacteria free medical journals lactic acid bacteria famous journals lactic acid bacteria Google Scholar indexed journals fermentation process articles fermentation process Research articles fermentation process review articles fermentation process PubMed articles fermentation process PubMed Central articles fermentation process 2023 articles fermentation process 2024 articles fermentation process Scopus articles fermentation process impact factor journals fermentation process Scopus journals fermentation process PubMed journals fermentation process medical journals fermentation process free journals fermentation process best journals fermentation process top journals fermentation process free medical journals fermentation process famous journals fermentation process Google Scholar indexed journals fermentation power articles fermentation power Research articles fermentation power review articles fermentation power PubMed articles fermentation power PubMed Central articles fermentation power 2023 articles fermentation power 2024 articles fermentation power Scopus articles fermentation power impact factor journals fermentation power Scopus journals fermentation power PubMed journals fermentation power medical journals fermentation power free journals fermentation power best journals fermentation power top journals fermentation power free medical journals fermentation power famous journals fermentation power Google Scholar indexed journals yeast articles yeast Research articles yeast review articles yeast PubMed articles yeast PubMed Central articles yeast 2023 articles yeast 2024 articles yeast Scopus articles yeast impact factor journals yeast Scopus journals yeast PubMed journals yeast medical journals yeast free journals yeast best journals yeast top journals yeast free medical journals yeast famous journals yeast Google Scholar indexed journals fermentation period articles fermentation period Research articles fermentation period review articles fermentation period PubMed articles fermentation period PubMed Central articles fermentation period 2023 articles fermentation period 2024 articles fermentation period Scopus articles fermentation period impact factor journals fermentation period Scopus journals fermentation period PubMed journals fermentation period medical journals fermentation period free journals fermentation period best journals fermentation period top journals fermentation period free medical journals fermentation period famous journals fermentation period Google Scholar indexed journals

Article Details

1. Introduction

Sourdough bread is widely consumed in regions such as northern Europe and U.S. It is characterized by its unique flavor and sourness, which depend on the sourdough used to make the bread. Sourdough is rich in organic acids produced by lactic acid bacteria (LAB), and LAB and yeast are concentrated in the sour dough [1, 2]. Because the protease activity of LAB is high, sourdough bread contains abundant peptides and amino acids [3, 4]. The organic acids produced by LAB help to improve the preservability of bread by preventing the growth of Bacillus spp. [1]. Lactobacillus brevis, L. plantarum and L. fermentum?were discovered from several sourdoughs [5]. Saccharomyces exiguous, Candida milleri and Candida humilis have been identified from spontaneously fermented sourdough [1, 6, 7]. Lactobacillus paracasei NFRI 7415 has been confirmed to be an LAB isolated from a traditional Japanese fermented fish called funa-sushi, and the pH sharply decreases with the growth of the cells [8, 9]. A large amount of organic acid (such as lactic acid) could thus be expected to be produced in the fermentation process by the addition of strain NFRI 7415 to dough. Some baker’s yeasts (Saccharomyces cerevisiae) isolated in our laboratory have some strains with excellent fermentation properties and can be used for bread making [10, 11]. In this study, we focused on various effects of LAB and yeast on sourdough bread. We attempted to develop a new sourdough bread using wild yeast isolated from fruit and LAB isolated from funa-sushi. The wild yeast used for the experiment was selected from S. cerevisiae isolated from fruits and soil, and this yeast was significantly preferred in sensory testing. The sourdough was fermented with LAB and yeast under 28°C and under 8°C. We carried out the fermentation for 4 days to investigate the amount of CO2 produced and the changes in the contents of organic acid and free amino acid with time. We chose conditions with high fermentation power from four different sourdoughs and created sourdough bread as a starter.

2. Materials and Methods

2.1 Strains and media

Lb. paracasei NFRI 7415 (hereinafter referred to as ‘LAB’) was isolated from funa-sushi [8]. We used wild yeast 10-2 (S. cerevisiae) isolated from apple leaves [10]. MRS agar medium (Difco Laboratories, Detroit, MI) was used for culturing the LAB. YM agar medium (1% glucose, 0.5% peptone, 0.3% yeast extract, 0.3% malt extract, pH 6.8) was used for culturing the yeast.

2.2 Preparation of the LAB and yeast

The LAB was inoculated on the MRS agar medium and incubated at 37°C for 48 hr. After incubation, the LAB colonies were transferred into a 15-mL tube containing MRS medium and incubated at 37°C for 24 hr. Then, 1 mL of pre-culture solution was transferred in 1,000 mL of MRS medium and anaerobically incubated at 37°C for 48 hr. The yeast was inoculated on the YM agar medium and incubated at 30°C for 48 hr. The yeast colonies were transferred into a 100 mL Erlenmeyer flask containing YM medium and incubated at 30°C for 24 h with 150-rpm shaking. Then, 1 mL of pre-culture solution was transferred into a 500 mL Erlenmeyer flask containing YM medium and incubated at 30°C for 48 h with 150-rpm shaking. Both cultures were centrifuged at 3,000 rpm for 10 min, and the precipitate was recovered. The collected precipitate was suspended in sterilized water, respectively. Then they were centrifuged at 3,000 rpm for 10 min, both supernatants were removed, and the collected the LAB and the yeast [12].

2.3 Preparation of sourdough

We prepared the sourdough according to the method described by Ohnishi et al. [13]. The following ingredients of sourdough were mixed: 20 g of flour, 10 g of rye flour, 15 g of water, 1.8 g of LAB, and 1.2 g of yeast collected as described above in section 2.2. We then conducted 4-day-long fermentation tests of four types of sourdough: LAB and yeast at 28°C ‘LAB+y28’, alone at 28°C ‘LAB28’, LAB+ yeast at 8°C ‘LAB+y8’and LAB alone at 8°C ‘LAB8’ for 4 days were carried out. Four samples of each type of sourdough were then place together in a bowl and covered a wet dishcloth. One gram was taken from each sample every day and suspended with 10 mL of sterilized water. The number of bacteria and the pH were then measured. The amount of CO2 produced during the fermentation was determined from the weight of the sourdough which started fermentation and the weight of the sourdough after fermentation.

2.4 Determination of organic acids and free amino acids in the sourdough

A part of each sourdough type was sampled every 24 h during the fermentation period, then freeze-dried, powdered and subjected to the quantification of organic acid and free amino acid as described. For the organic acid analysis, a 1-g sample was extracted with 10 mL of 70% ethanol at 50°C for 30 min and centrifuged at 3,000 rpm for 10 min. The residue was further extracted two more times, and all of the extracts were combined and evaporated by rotary vacuum evaporation. The concentrates were diluted to 3 mmol/L of perchloric acid solution and filtered through a 0.45 µm syringe filter (Millipore, Milford, MA). The organic acid in the four sourdoughs quantified by high-performance liquid chromatography (HPLC) (UV L-7405, Hitachi). The samples were applied to a GL-C610H-S column (300 mm × 7.8 mm; flow rate, 0.5 ml/min; oven temperature, 60°C; injection volume, 20 µl; Hitachi Chemical, Tokyo), and UV absorbance was measured at 440 nm. Citric acid, tartaric acid, malic acid, succinic acid, lactic acid, acetic acid, propionic acid, isobutyric acid and n-butyric acid were used as a standard solution. The concentration of organic acids in the sourdough was calculated by the absolute calibration curve method.

For the free amino acid analysis, a 0.5 g sample was extracted with 20 mL of 70% ethanol at 50°C for 30 min, and centrifuged at 3,000 rpm for 10 min. The residue was further extracted two more times, and all of the extracts were combined and evaporated by rotary vacuum evaporation. The concentrates were diluted to 25 mL of lithium citrate buffer (pH2.2) and filtered through a 0.45 µm syringe filter (Millipore). The free amino acids in four sourdoughs were analyzed by an amino acid automatic analyzer (L-8800, HITACHI). Thirty-one types of free amino acids including 11 types of non-proteinogenic amino acids were used as a standard solution.

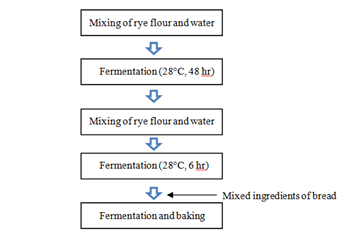

2.5 Preparation of the sourdough bread

The sourdough bread was prepared according to the Australian traditional method (Figure 1) [14]. Two types of sourdough were used for bread making: (LAB+y28) and (LAB28) for 48 hr. First, 48 g of sourdough fermented at 28°C for 48 h (LAB+y28) and 48 g of sourdough fermented at 28°C for 48 h (LAB28) were respectively added to 50 g of rye flour and 50 g water. The ingredients were mixed and fermented at 28°C for 6 h. After fermentation, 67.5 g of sourdough was mixed with 70 g rye flour, 112.5 g of wheat flour, 4 g of salt, and 125 g of water. The sourdough bread was then baked in a Siroca home bakery (SHB-112, Oku Sale Co., Japan). The two types of sourdough bread were sliced at about 1-cm thickness and lyophilized. Free amino acids were measured as described above.

Figure 1: Sourdough bread production process.

3. Results

3.1 Characteristics of the fermentation of sourdough

The number of LAB in sourdough fermentation reached 108cfu/g within 2 days in all of the dough types. The number of LAB in the LAB+y28 sourdough reached 109cfu/g on day 3 (Table 1). Regarding the number of yeast, the yeast numbers of the LAB+y28 and LAB+y8 sourdoughs were increased with the passage of time and decreased after 3 days (Table 2).

|

Sourdough |

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

|

LAB+Yeast (28°C) |

1.0 × 106 |

1.0 × 107 |

3.7 × 108 |

1.3 × 109 |

3.0 × 108 |

|

LAB (28°C) |

3.0 × 106 |

3.0 × 107 |

1.9 × 108 |

5.1 × 108 |

2.6 × 108 |

|

LAB+Yeast (8°C) |

1.0 × 106 |

1.0 × 107 |

3.6 × 108 |

3.8 × 108 |

3.0 × 108 |

|

LAB (8°C) |

4.0 × 106 |

4.0 × 107 |

6.7 × 108 |

8.0 × 108 |

8.0 × 108 |

Table 1: The number of Lb. paracasei NFRI 7415 in sourdough during fermentation (cfu/g).

|

Sourdough |

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

|

LAB+Yeast (28°C) |

2.6 × 106 |

2.6 × 106 |

1.0 × 108 |

1.1 × 109 |

1.0 × 108 |

|

LAB+Yeast (8°C) |

2.0 × 106 |

2.0 × 107 |

1.0 × 108 |

4.1 × 108 |

2.5 × 105 |

Table 2: The number of wild yeasts (10-2) in sourdough during fermentation (cfu/g).

Changes in the CO2 production and pH during the fermentation process are shown in Figure 2. On the first day from the start of the fermentation, the CO2 production of the LAB28 sourdough was higher than that of the LAB+y28 sourdough. However, the CO2 production of the LAB+y28 sourdough was higher than that of the LAB28 sourdough on the second day. On day 4 of fermentation, the pH values of the LAB+y28 and LAB28 sourdoughs were approx. 3.3, and those of the LAB+y8 and LAB8 sourdoughs were approx. 3.7.

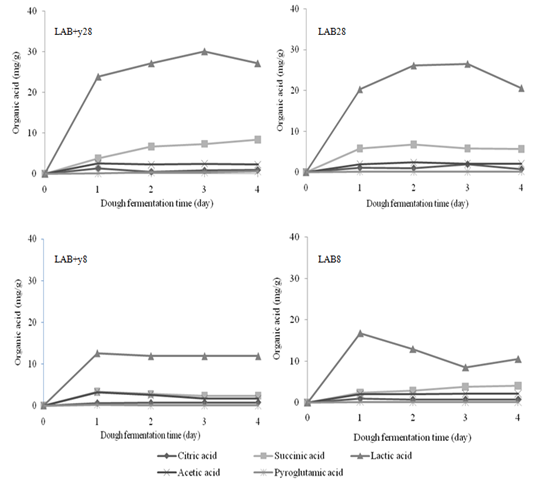

3.2 Organic acid and free amino acid composition of the sour dough

The organic acid contents in the sourdough during fermentation are shown in Figure 3. The highest organic acid content was lactic acid in all of the types of sourdough. Lactic acid was particularly increased in the sourdough fermented at 28°C (LAB+y28), and succinic acid tended to increase. Although citric acid, acetic acid, and pyroglutamic acid were detected in all of the sourdoughs, their production levels were low, and no significant difference was observed based on the fermentation process. The production of total organic acids in sourdough fermented at 28°C (LAB+y28) and (LAB28) was appox. twice that in the sourdough fermented at 8°C (LAB+y8) and (LAB8).

Figure 2: Changes in CO2 production and pH in sourdough during fermentation.

Figure 3: Changes of organic acid contents in sourdough during fermentation.

The total free amino acid contents of the sourdoughs during fermentation are shown in Tables 3 and 4. Free amino acids of the sourdoughs fermented at 28°C (LAB+y28 and LAB28) increased as the fermentation progressed (Table 3). The total free amino acids of the sourdoughs fermented at 8°C (LAB+y8 and LAB+y8) decreased after 3 days (Table 4). The total free amino acid content of the LAB+y28 sourdough was highest among the four samples during the fermentation period. All free amino acids except for alanine were increased in the LAB+y28 sourdough at 4 days (Table 3). In the fermentation at 8°C (the LAB+y8 and LAB8 sourdoughs), glutamic acid, alanine, leucine and arginine were increased, but no significant change was observed in the other free amino acids (Table 4).

|

Asp |

LAB + yeast (28°C) |

LAB (28°C) |

||||||||

|

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

|

|

20.0 |

2.9 |

0.9 |

1.6 |

1.1 |

26.2 |

11.7 |

2.0 |

3.5 |

2.0 |

|

|

Thr |

1.5 |

4.4 |

11.6 |

9.7 |

11.0 |

2.0 |

5.8 |

6.9 |

4.9 |

5.1 |

|

Ser |

2.6 |

5.4 |

13.7 |

11.6 |

13.5 |

3.4 |

8.8 |

10.8 |

7.8 |

8.1 |

|

Asn |

22.7 |

5.6 |

9.6 |

9.8 |

10.1 |

35.1 |

28.6 |

20.2 |

20.1 |

15.4 |

|

Glu |

12.1 |

25.2 |

50.2 |

47.0 |

49.9 |

13.8 |

24.6 |

43.9 |

39.0 |

40.1 |

|

Gln |

7.3 |

8.2 |

24.3 |

23.6 |

28.6 |

9.0 |

8.8 |

18.7 |

12.6 |

15.3 |

|

Pro |

5.3 |

13.7 |

23.0 |

23.8 |

25.4 |

8.0 |

14.3 |

20.8 |

19.6 |

22.3 |

|

Gly |

2.5 |

9.0 |

17.1 |

14.8 |

16.1 |

2.8 |

10.9 |

16.7 |

15.0 |

15.4 |

|

Ala |

8.2 |

40.5 |

71.6 |

67.1 |

70.7 |

8.7 |

41.9 |

73.0 |

66.1 |

67.0 |

|

Val |

2.6 |

10.7 |

30.6 |

23.1 |

26.7 |

3.6 |

13.5 |

27.6 |

25.1 |

24.0 |

|

Met |

0.1 |

5.2 |

12.9 |

11.3 |

12.9 |

0.8 |

7.4 |

11.3 |

9.6 |

10.5 |

|

Ile |

1.4 |

6.3 |

18.0 |

15.0 |

17.5 |

1.9 |

7.4 |

13.9 |

11.7 |

12.7 |

|

Leu |

1.6 |

18.6 |

59.7 |

50.9 |

59.6 |

2.2 |

25.1 |

50.3 |

40.8 |

45.6 |

|

Tyr |

1.8 |

9.2 |

23.4 |

20.9 |

23.4 |

2.2 |

9.8 |

19.4 |

16.7 |

18.4 |

|

Phe |

1.8 |

12.8 |

37.7 |

33.7 |

38.5 |

2.0 |

15.0 |

32.5 |

26.9 |

30.2 |

|

GABA |

8.3 |

12.4 |

17.9 |

18.2 |

17.2 |

9.0 |

18.1 |

19.3 |

19.4 |

17.8 |

|

Trp |

6.4 |

6.9 |

12.4 |

13.0 |

12.7 |

8.9 |

10.3 |

12.6 |

10.1 |

8.8 |

|

Orn |

0.9 |

1.6 |

1.8 |

1.7 |

1.9 |

0.3 |

0.6 |

0.6 |

0.7 |

0.7 |

|

Lys |

1.3 |

8.0 |

23.0 |

20.6 |

23.8 |

2.0 |

9.3 |

14.1 |

11.2 |

12.5 |

|

His |

1.4 |

3.0 |

5.4 |

5.0 |

5.4 |

1.4 |

3.4 |

3.8 |

3.2 |

3.2 |

|

Arg |

5.3 |

19.5 |

38.2 |

36.6 |

40.1 |

5.4 |

19.7 |

31.5 |

27.5 |

29.6 |

|

Total |

126.1 |

265.4 |

538.1 |

495.0 |

546.1 |

157.4 |

332.3 |

488.2 |

416.0 |

442.5 |

Table 3: The free amino acid content of sourdough during fermentation (mg/100 g).

|

Asp |

LAB + yeast (8°C) |

LAB (8°C) |

||||||||

|

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

day 0 |

day 1 |

day 2 |

day 3 |

day 4 |

|

|

24.4 |

18.6 |

16.9 |

17.0 |

13.7 |

28.3 |

19.8 |

20.2 |

24.8 |

22.1 |

|

|

Thr |

2.0 |

1.7 |

2.4 |

1.9 |

1.9 |

2.0 |

3.0 |

4.7 |

4.7 |

5.0 |

|

Ser |

3.3 |

2.6 |

3.2 |

2.8 |

2.7 |

3.4 |

5.1 |

7.3 |

7.4 |

7.7 |

|

Asn |

29.0 |

15.9 |

12.7 |

14.5 |

10.4 |

36.3 |

29.2 |

31.8 |

34.9 |

31.5 |

|

Glu |

15.7 |

13.3 |

18.2 |

18.5 |

16.2 |

15.9 |

5.8 |

9.1 |

10.8 |

11.7 |

|

Gln |

9.8 |

11.1 |

14.9 |

13.3 |

14.5 |

9.4 |

8.1 |

10.2 |

10.0 |

10.3 |

|

Pro |

7.7 |

9.4 |

12.2 |

8.6 |

10.8 |

8.6 |

8.3 |

10.3 |

9.9 |

7.2 |

|

Gly |

3.0 |

6.5 |

9.9 |

8.4 |

8.5 |

2.8 |

6.2 |

9.0 |

8.5 |

8.8 |

|

Ala |

10.4 |

23.0 |

33.3 |

30.4 |

29.5 |

8.8 |

17.6 |

25.3 |

24.3 |

25.4 |

|

Val |

5.1 |

4.2 |

7.3 |

6.9 |

7.4 |

3.7 |

5.2 |

8.7 |

9.1 |

12.3 |

|

Met |

0.2 |

1.7 |

2.2 |

1.9 |

1.9 |

0.8 |

2.7 |

3.3 |

3.5 |

5.0 |

|

Ile |

1.8 |

2.2 |

2.9 |

2.8 |

2.9 |

1.9 |

3.5 |

4.5 |

5.0 |

5.3 |

|

Leu |

2.1 |

3.3 |

5.8 |

4.6 |

5.1 |

2.1 |

4.8 |

9.5 |

10.3 |

12.0 |

|

Tyr |

2.2 |

3.2 |

4.7 |

4.8 |

5.0 |

2.2 |

3.0 |

4.4 |

4.4 |

4.9 |

|

Phe |

2.2 |

2.9 |

5.5 |

5.3 |

5.0 |

2.2 |

2.7 |

5.2 |

5.8 |

6.8 |

|

GABA |

10.0 |

11.4 |

15.5 |

14.0 |

13.3 |

8.2 |

15.0 |

18.3 |

18.3 |

17.4 |

|

Trp |

8.0 |

7.4 |

8.5 |

8.7 |

6.9 |

9.0 |

8.2 |

9.3 |

9.1 |

8.7 |

|

Orn |

1.1 |

1.3 |

1.4 |

1.4 |

1.5 |

0.4 |

0.5 |

0.4 |

0.4 |

0.4 |

|

Lys |

1.9 |

3.8 |

5.4 |

4.3 |

4.9 |

2.0 |

4.0 |

7.8 |

7.9 |

8.8 |

|

His |

1.6 |

2.8 |

3.3 |

2.9 |

2.9 |

1.7 |

2.3 |

3.3 |

3.1 |

3.5 |

|

Arg |

6.6 |

10.5 |

14.4 |

13.7 |

14.4 |

5.5 |

7.6 |

12.5 |

13.0 |

14.0 |

|

Total |

155.6 |

187.5 |

236.9 |

216.4 |

208.0 |

164.1 |

187.2 |

244.8 |

246.8 |

243.3 |

Table 4: The free amino acid content of sourdough during fermentation (mg/100 g).

3.3 Free amino acid contents of the sourdough bread

Total amino acids in the LAB+y28 sourdough bread were higher than that of sourdough bread the LAB28 sourdough bread (Table 5). The contents of glycine, alanine, leucine, phenylalanine and arginine in the LAB+y28 sourdough bread were higher than those of the LAB28 sourdough bread. The aspartic acid and asparagine levels of the LAB28 sourdough bread were higher than those of the LAB+y28 sourdough bread.

|

LAB+yeast (28°C) |

LAB (28°C) |

|

|

Asp |

13.8 |

14.7 |

|

Thr |

8.1 |

4.6 |

|

Ser |

10.4 |

6.1 |

|

Asn |

17.8 |

20.4 |

|

Glu |

42.6 |

32.4 |

|

Gln |

18.5 |

9.5 |

|

Pro |

23.7 |

19.1 |

|

Gly |

13.0 |

10.3 |

|

Ala |

46.6 |

43.0 |

|

Val |

23.0 |

17.6 |

|

Met |

7.7 |

4.6 |

|

Ile |

12.5 |

8.1 |

|

Leu |

41.7 |

26.1 |

|

Tyr |

17.7 |

11.8 |

|

Phe |

28.6 |

18.6 |

|

GABA |

18.3 |

15.9 |

|

Trp |

12.4 |

8.0 |

|

Orn |

1.9 |

0.7 |

|

Lys |

18.4 |

10.1 |

|

His |

4.5 |

2.7 |

|

Arg |

35.0 |

23.1 |

|

Total |

424.9 |

329.9 |

Table 5: Content of free amino acid of sourdough bread and LAB bread (mg/100 g).

4. Discussion

The CO2 productions of the sourdoughs fermented at 28°C (LAB+y28 and LAB28) were greatly than those of the sourdoughs fermented at 8°C (LAB+y8 and LAB8). Compared to the LAB+y28 and LAB28 sourdoughs, the CO2 production in the LAB+y28 sourdough was higher than that of the LAB28 sourdough. We speculate that the CO2 production in the sourdough was increased at the same time that the sourdouhs’ pH decreased. In the fermentation test in the YM medium at 30°C of only the wild yeast (10-2) isolated from apple leaves, the pH of the YM medium at 4 days remained around 3.5 [11]. In the same experiment in another study using YM medium, the number of yeasts was also 108-109 cfu/mL [10], which is in almost complete agreement with the number of yeasts in the present study’s sourdough. Our results thus suggest that LAB and yeast coexist without inhibiting the growth of the other. As the pH of the LAB+y28 sourdough decreased to pH 3.3 (Figure 1), we inferred that LAB produced a large amount of organic acid. Because the numbers of LAB and yeasts in the LAB+y28 sourdough (A) were decreased after 3 days, we conclude that the most suitable temperature and fermentation period for the sourdough are 28°C and 2-3 days.

Rye flour used for sour bread does not form gluten like flour; the lactic acid produced by the fermentation of sourdough swells protein and gives extensibility [1, 2]. It was reported that LAB was necessary for making bread when using rye flour [1]. The amount of lactic acid in rye sourdough (10°C, 40 h fermentation) using Lactobacillus sakei and beer yeast S. serevisiae separated from sake was 815 mg/100g [4]. In the present study, the lactic acid production in the sourdough at 8°C (LAB+y8) on day 2 was 11.9 mg/g (1,190 mg/100 g). Lb paracasei NFRI 7415 showed high lactic acid-producing ability.

After the fermentation of the four types of sourdough, the total free amino acids of the LAB+y28 and LAB28 sourdoughs were approximately twice those of the LAB+y8 and LAB8 sourdoughs (Tables 3 and 4). The free amino acids affect breads’ aroma and taste. L-glutamic acid is involved in umami (savory taste) and glycine and alanine are involved in sweetness [15, 16]. In the sourdoughs fermented herein at 28°C (LAB+y28 and LAB28), the alanine and glutamic acid levels were increased by fermentation, which we suspect improves the taste and flavor of sourdough bread.

It was reported that the total free amino acid contents in sourdough depend on the type of LAB used [1]. L. sakei accumulated total free amino acids of approx. 10,000 µmol/kg (1 mmol/100 g) in sourdough (wheat flour: rye flour=2:1) with 24 hr of fermentation [1]. Converted into the molar concentration in the present study, the total free amino acid contents of the LAB+y28 and LAB+y8 sourdough breads were 5.10 mmol/100 g and 3.18 mmol/100 g, respectively. Lb. paracasei NFRI 7415 is gram-positive and homofermentatative, and it converts glucose to 100% lactic acid [7]. L. sakei is also a homofermentatative LAB, and the free amino acids accumulated remarkably with L. sakei [1].

In summary, Lb. paracasei NFRI 7415 produced the free amino acids and lactic acid at high concentrations in sourdough due to coexistence with S. cerevisiae (10-2). Our results demonstrate that it is possible to develop new sour bread using sourdough by a co-fermentation of LAB and wild yeast.

5. Conclusion

Four types of sourdough was prepared using Lb. paracasei NFRI 7415 and S. cerevisiae (10-2) isolated in our laboratory, and 4-day fermentation tests were carried out. Based on the resulting CO2 production and organic acid and free amino acid contents, we determined that the most suitable temperature and fermentation period for the sourdough and temperature are 28°C and 3 days.

Acknowledgment

This study was supported by The Public Foundation of Elizabeth Arnold-Fuji (2015- 2016).

Conflict of Interests

The authors declare that they have no conflict of interests.

References

- Ozaki M. A new genealogy of lactic acid fermentation. Chuohoki Publishing (2004): 206-224.

- Okada S. Dough fermentation and lactic acid bacteria. Japan Society for Lactic Acid Bacteria 9 (1999): 82-85.

- Shima J. Microbial function supporting bread making: Focusing on yeast and lactic acid bacteria. The Society for Biotechnology 91 (2013): 618-620.

- Toshihide Nakamura, Ayako Yoshida, Noriko Komatsuzaki, et al. Isolation and characterization of a low molecular weight peptide contained in sourdough. J Agric Food Chem 55 (2007): 4871-4876.

- Haruhiko Mori, Hisasi Okada, Hiroshi Onishi, et al. Bread making using brewing microorganisms (Part 2) Sour bread making using the new starter. J Brew Soc Japan 96 (2001): 360-367.

- Lattanzi A, Minervini F, Di Cagno R, et al. The lactic acid bacteria and yeast microbiota of eighteen sourdoughs used for the manufacture of traditional Italian sweet leavened baked goods. Int J Food Microbiol 163 (2013): 71-79.

- Gullo M, Romano AD, Pulvirenti A, et al. Candida humilis-dominant species in sourdoughs for the production of durum wheat bran flour bread. Int J Food Microbiol 80 (2002): 55-59.

- Komatsuzaki N, Shima J, Kawamoto S, et al. Production of γ-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22 (2005): 497-504.

- Komatsuzaki N, Nakamura T, Kimura T, et al. Characterization of glutamate decarboxylase from a high γ-aminobutyric acid (GABA)-producer, Lactobacillus paracasei. Biosci Biotechnol Biochem 72 (2008): 278-285.

- Komatsuzaki N. Characteristics of Saccharomyces cerevisiae isolated from fruits and humus: Their suitability for bread making. Progress in Biological Sciences 6 (2016): 1-9.

- Noriko Komatsuzaki, Hiroyuki Kamishima, Shinobu Fujihara, et al. Fermentation characteristics of yeast suitable for high-sugar dough. Journal for the Integrated Study of Dietary Habits 27 (2016): 15-21.

- Nishida O, Kuwazaki S, Suzuki C, et al. Superior molasses assimilation, stress tolerance, and trehalose accumulation of baker’s yeast isolated from dried sweet potatoes (hoshi-imo). Biosci Biotechnol Biochem 68 (2004): 1442-1448.

- Onishi H, Okada H, Kajitani T, et al. Bread making using brewing microorganisms (Part 3); The free acid composition and shelf life of bread with added of lactic acid bacteria and its effects on the atherogenic index of rats. J Brew Soc Japan 97 (2001): 219-227.

- Echigo K. Study of bread: From cultural history to preparation. Shibata Bookstore (1992): 130-131.

- Fujimoto A. Relationship between the deliciousness of traditional bread dough and microorganisms. The Society for Biotechnology, Japan 90 (2012): 329-334.

- Sugawara T. Food science I, Kenpakusha (2012): 68.

Impact Factor: * 3.8

Impact Factor: * 3.8 CiteScore: 2.9

CiteScore: 2.9  Acceptance Rate: 11.01%

Acceptance Rate: 11.01%  Time to first decision: 10.4 days

Time to first decision: 10.4 days  Time from article received to acceptance: 2-3 weeks

Time from article received to acceptance: 2-3 weeks