Crambe Abyssinica Oil as Raw Material for Renewable Fuel Production-Review

Francisco Aléxis Dntas Maia1*, Amanda Duarte Godim1, Anne Gabriella Dias Santos2, Márcio Cleivo de Morais Souza1, Vasco de Lima Pinto1, Aruzza Mabel de Morais Araújo1

1Federal University of Rio Grande do Norte, Brazil

2State University of Rio Grande do Norte, Brazil

*Corresponding author: Francisco Aléxis Dntas Maia, Federal University of Rio Grande do Norte, Brazil.

Received: 18 May 2023; Accepted: 23 May 2023; Published: 25 August 2023

Article Information

Citation: Francisco Aléxis Dntas Maia, Amanda Duarte Godim, Anne Gabriella Dias Santos, Márcio Cleivo de Morais Souza, Vasco de Lima Pinto, Aruzza Mabel de Morais Araújo. Crambe Abyssinica Oil as Raw Material for Renewable Fuel Production- Review. Journal of Biotechnology and Biomedicine 6 (2023): 322-330.

DOI: 10.26502/jbb.2642-91280094

View / Download Pdf Share at FacebookAbstract

This paper presents information about Crambe Abyssinica Hochst and discusses various aspects of oil planting, extraction and treatment, chemical composition, and the physical and chemical properties of the oil. In addition, it discusses the possibility of its use as a raw material for biofuels. Crambe Abyssinica Hochst is an oilseed from the Mediterranean that has good oil content in its seed (~ 38%). Other advantages are presented as the short growth period and can be grown in environments considered unsuitable, which are desirable requirements for use in the production of biofuels. Crambe oil has erucic acid as its main fatty acid, which is not edible, so it is an oil that does not compete with the food industry. This crop is already used in the industry in various parts of the world for the production of various products, including biodiesel with oxidative stability considered promising.

Keywords

<p>Crambe Abyssinica Hochst; Oil; Biodiesel; Biofuels; Environment</p>

Article Details

Introduction

Renewable energy sources such as wind energy, solar energy, biomass in general (traditional and modern), large hydroelectric and geothermal, account for approximately 17.7% of all energy demand in the world. The rest of the energy comes from fossil fuels [1]. In Brazil, the amount of renewable energy had a total demand in 2020 of approximately 47.6%. Biomass corresponded to 8.6% of this value in 2020, increasing compared to 2019 which was 8.4% [2]. The global peak of energy consumption and greenhouse gas emissions is around 13.7 Mtoe and 32 GtCO2. The transport sector (which mainly uses fossil fuel sources) is one of the main consumers of energy, being responsible for emitting 25% of all greenhouse gases [3]. Oil, one of those responsible for the emission of greenhouse gases, is still the main source for energy production worldwide. With this, the rulers have a great challenge, to reduce the polluting gases emitted in the generation of energy in order to reduce climate change and environmental pollution. The generation of clean energy is an option to solve this problem, therefore, there is a need for investment in Renewable Energy [4].

Renewable energy is that generated by renewable raw material, that is, capable of regenerating itself. The raw materials are the sun, wind, biomass, running water, geothermal energy, among others [5]. Among the advantages of using renewable energy is the benefit to the environment. In the production of these energies, natural resources are not consumed permanently, there is a reduction in the amount of raw material and energy used in production, they generate less waste, emit less polluting gases, including greenhouse gases (GHG) and still provide economic growth [6]. Four important areas must be taken into consideration for the production of renewable energies: the generation of jobs, production costs, safety and the environment. Furthermore, climatic, geographic and economic conditions must be taken into account [5]. In addition, sustainability is an important factor to be quantified for clean energy sources, since there are several production processes for each type of renewable energy [7].

When it comes to sustainability, the Greenhouse Gas Emissions Estimation System (SEEG) shows that the second largest emitter of GHGs is the energy sector. It is expected that replacing energy from fossil sources with clean energy will considerably reduce the emission of gases that harm the environment. Brazil has several resources for the synthesis of clean energy, the production of liquid biofuels for use in engines (such as ethanol and biodiesel) are examples that use these resources. Already consolidated in our country, anhydrous ethanol can partially replace gasoline and hydrated ethanol can be used in flex-fuel cars, completely replacing gasoline with the advantages of being renewable and reducing GHG emissions [8]. To encourage the use of clean energy, Law 13,576/2017, National Biofuel Policy, was created to promote biofuels in Brazil through the RenovaBio Program. The objective is to encourage the production of various biofuels by creating a decarbonization market, better known as CBio, in order to reduce the emission of polluting gases. In order to reach the GHG reduction target established at the 21st Paris Climate Conference (COP21), Brazil will have to produce at least 46,106 m3 of ethanol by 2028 to reduce by 10% the amount of GHG emitted by means of transport [9].

The reduction of greenhouse gases involves the use of biomass to produce biofuels. Biomass is a raw material that can be of animal or vegetable origin and generates clean energy that emits less polluting gases into the environment compared to fossil raw material [10]. Even though they are edible crops and compete with the food industry, they are economically viable for the production of biofuels [11]. When choosing a biomass, the production regime, the type of cultivated species and the influence on the energy efficiency index are parameters to be analyzed. That said, it is important that a clean source of energy serves specifically for energy purposes without competing with the food industry, whether it is an oilseed crop or not [5]. Among the inedible oilseeds are jatropha [12], castor bean [13], oiticica [14] and Crambe [15]. These oils, in addition to not competing with the food industry, can be grown in different soil systems, reducing the final cost of production [16].

Oil plants are widely used to obtain biofuels, including biodiesel. Crops that produce edible and non-edible oils such as soybean [17], palm [6], rapeseed [18], sunflower [19], canola [20], residual oil [20] among others are widely cited in the literature. The most used process for biodiesel production is transesterification. In this process, vegetable oil reacts with an alcohol (usually of low molecular weight) in an acidic or basic medium, forming triglycerides and glycerol [21]. The production of biodiesel from vegetable oils is seen as an easy chemical conversion to be achieved, achieving good yield and good quality. Biodiesel does not contain sulfur or aromatic compounds, it is biodegradable, does not have toxic characteristics, is oxygenated and is usually rich in hexadecane [22]. Since 2008, diesel sold in Brazil contains biodiesel. The Brazilian National Program for the Production of Biodiesel Use (PNPB), from 2013, allowed the use of B5, that is, with 5% of biodiesel. This biodiesel percentage value increased, reaching B10 in 2018 [23]. In April of this year (2023), the percentage reached 12%, a resolution approved by the National Council for Energy Policy (CNPE) and a progressive increase of 15% until 2026. This measure provides for an increase of two cents in the final price of B12 diesel sold at gas stations [24].

In addition to biodiesel, recently biohydrocarbons have also been studied. Being able to be generated through lignocellulosic residues and fatty materials, they are known as drop-in biofuels [25]. Drop-in biofuels are liquid hydrocarbons chemically equivalent to their fossil analogues and with similar physicochemical properties, however they are produced with renewable raw material. One of the advantages of using these biofuels is that there is no need to change engines for their use. Among the drop-in biofuels are biokerosene (BioQAv) and green diesel [26]. Aviation biokerosene is formed by products with a carbon chain with around 9 to 16 carbons and green diesel in the range of 15 to 21 carbons [25]. The aviation industry has been under pressure both for the manufacture of aircraft that have greater energy efficiency, as well as for the production of biokerosene to replace fossil kerosene. It is an important action, seen as the solution for CO2 mitigation [27]. The challenge of producing drop-in biofuels is to meet specifications similar to those of fossil origin, such as humidity, oxidative stability, heat, light, metals and storage time [28]. For the construction of this review on Crambe, some articles were analyzed. Table 1 brings these articles according to the central themes defined by the authors.

|

Manuscript |

Reference main |

|

Crambe Abyssinica Planting and Production |

[29]; [30]; [31]; [5]; [32] |

|

Crambe Abyssinica oil production |

[31]; [16]; [29]; [33] |

|

Oil Composition and Properties |

[32]; [34];[23] |

|

Biodiesel production from Crambe Abyssinica oil |

[35]; [16]; [36]; [37] |

|

Other fuels |

[26]; [38]; [39]; [40] |

|

Other products |

[41]; [42]; [43]; [44] |

|

Source: Author Himself (2020). |

|

Table 1: Main manuscript on Crambe Abyssinica

In this review, an overview was given of the potential of Crambe oil for the production of liquid fuels (biodiesel) and new generation fuel (renewable hydrocarbons). In addition, it reports recent research on the production and implementation of Crambe oil in Brazil, chemical compositions, physicochemical properties of the oil and value-added co-products.

Main goal

Evaluate the main properties of Crambe Abyssinica Hochst as biomass for biofuel production

Specific objectives

- Carry out a survey of the planting conditions of Crambe Abyssinica Hochst;

- Evaluate the properties of biodiesel produced from Crambe oil;

- Identify the main characteristics and fatty acids of crambe oil;

- Evaluate the possibility of producing Drop-in fuels using crambe oil.

Methodology

The methodology for this review was based on [45]. In this model, the review is divided into three stages, and each stage has some phases to be overcome. In the first stage, a revision planning was made. In phase one of this stage, the need for this review was identified, since the biomass Crambe Abyssinica Hochst is not cited for the production of Drop-in fuels. In this sense, there was a need to carry out a study of art in order to learn about some of the works carried out with this raw material. Phase two of this stage was the planning and preparation of the review proposal. Phase three and the last phase of this stage, the protocol was made. In this phase it was chosen which articles were included, how the search was carried out, which platform the articles were searched for and the keywords chosen for the searches.

In the second stage, the review was carried out. It was at this stage that the review protocol was put into practice. Phase one of this internship was to search for articles from research platforms. Phase two dealt with selecting the articles, for which the following parameters were used: objectivity of the articles, quality of the information disclosed and period of publication. In this case, priority was given to using articles that had been published for a maximum of 7 years. In phase three, the information and data selected in the articles were summarized. The third and final stage, it is about disseminating and reporting the synthesized data. This last stage has two phases. In phase one, the review was written and in phase two, submission for publication was made.

Planting and production of Crambe Abyssinica

Crambe Abyssinica Hochst, belonging to the Brassicacease (Crucifera) family [29], originally from the Mediterranean region, is a crop that generates an inedible oil. Its cultivation cycle is considered short, it can reach one meter in height, its roots are 15 cm in an aggressive root system and its flowers can be white or yellow [30]; [31]. Among its characteristics, some are highlighted below: in relation to the seeds, a thousand of them have a mass that varies between 6 and 10 g, measuring between 0.8 and 2.6 mm each unit. These characteristics make crambe credible as a biomass with good agronomic characteristics [31]. Several experimental studies report some important characteristics for the crambe culture and some of these studies are mentioned in table 2.

|

|

[16] |

[46] |

[47] |

[30] |

[48] |

|

City (Country) |

Portugal |

Rio Verde/ GO (Brazil) |

Botucatu/ SP (Brazil) |

Cascavel/ RS (Brazil) |

Italy |

|

Crambe Abyssinica seeds supplier |

Cultivar FMS-Brilante (MS-Brazil) |

Cultivar FMS-Brilante (MS-Brazil) |

Cultivar FMS-Brilante (MS-Brazil) |

Cultivar FMS-Brilante (MS-Brazil) |

Council for Economic Research and Agricultural Research - CREA (Bologna, Italy) |

|

Oil yield per hectare |

194 kg/ha |

120 kg/ha |

150 kg/ha |

194 kg/ha |

229 kg/ha |

|

Planted Area and/or measures |

Rows with 35cm between plants, 2cm deep, density of 100 plants /m2. |

Rows with 45cm between plants, 1220 plants /ha, 12 kg of seeds /ha. |

Rows with 34cm between plants, 4cm deep, 12 kg of seeds /ha. |

Rows with 30cm between plants, 3cm deep, 12 kg of seeds /ha. |

Rows with 23cm between plants, 12 kg of seeds / ha, density of 75 plants /m2. |

|

Soil composition |

- |

Dystrophic Red Latosol |

Dystrophic Red Latosol |

Dystrophic Red Latosol |

Fertile clay soil with subalkaline pH |

|

Weather Conditions |

Temperature day / night = 22 / 16 °C. 250mm of precipitation in the period. |

Temperature day / night = 35 / 20 °C. 1500 - 1800mm of precipitation per year. Humid tropical climate with rainy season in summer and dry in winter. |

62mm precipitation for the period. Tropical climate with dry winters and hot and rainy summers. |

Average temperature 21°C. 1620mm of precipitation per year. Local climate is temperate /mesothermal and super-humid. |

Average temperature of 18.1°C. 152.8mm of precipitation in the period. |

|

Harvest Period |

120 days |

88 days |

46 days |

110 days |

96 days |

|

Fertilizers and Nutrients |

Organic Matter for adjustments |

Phosphorus (18% P2O5) and Limestone (CaO = 30,5 % and MgO 18,7 %) |

NPK - nitrogen-phosphorus-potassium (formula N-P2O5-K2O 8:28:16) |

- |

30, 40 and 75 kg /ha of N, P and K, respectively |

Source: Author Himself (2020).

Table 2: Experimental studies on the culture of Crambe Abyssinica

The articles analyzed had Crambe cultivation in Portugal, Brazil and Italy (Table 2). But there are several works in other countries, such as Poland [5], India [49], China [50] among others. All the works cited in Table 2 purchased seeds from Cultivar Fundação MS-Brilhante no Brasil, a company in Mato Grosso do Sul, with the exception of [48] which received the seeds from the Council for Economic Research and Agricultural Research - CREA (Bologna, I). All authors considered the results in the amount of oil per hectare to be good, the reported values were between 120 and 229 kg per ha. It is important to highlight that the value cited by [48], considered the peeled seeds, while the other authors did not report this type of information, probably because they did not peel the seeds. The value of 150 kg/ha reached by [47], was at a cost of using 300 kg/ha of NPK fertilizer (N-P2O5-K2O 8:28:16), that is, even using fertilizer, it obtained the second lowest amount of oil. The plantations for the cultivation of Crambe are organized in rows that vary in distance between one sowing of another between 23 and 45 cm. In most cases, around 12 kg of seed are used per planted hectare, with the exception of [48] who used 18 kg and provided data in which they used a total area of 400 m2. The regions had similar soils in at least three of the five experiments. The Distroférric Red Latosol, a clayey soil that can also be called Ferralsol Argiloso Latosol. [16] did not report the type of soil used, but reported in their work the analysis of the soil used, such as: pH = 7.1; P (mg/kg) > 200; Organic Matter (% wt.) = 2.91; Ca (mg/kg) = 1737; K (mg/kg) > 200; Mg (mg/kg) = 52. In Italy, [48] reported that it is a fertile clayey soil. The authors reported that crambe cultivation occurred in a rotation regime for second crop use for soybeans, corn and wheat. The treatment against weeds or pests was not mentioned because the literature indicates that crambe is resistant to these diversities. Despite soil modifications and fertilizers, it did not seem to be a concern among the authors, since crambe can be grown on environmentally inappropriate, non-agricultural, arid and semi-arid lands [32]. Climatic conditions were different between growing conditions. Temperature ranged from 18 to 35 °C and rainfall ranged from 62 to 250 mm of precipitation. It was noticed that the precipitation volume did not influence the seed yield. Probably because the crop was irrigated, although only [16] mentioned that he used sprinkler irrigation. Other studies have already shown that this crop supports water restriction well [51]. All seeds were collected close to maturation, with the exception of [47] who performed the harvest after 46 days. Even though the harvest was done in half of the recommended period, the author achieved a good yield. The tests carried out with the addition of fertilizer in the soil had better results, both for yield and seed quantity and for the oil content extracted from the seeds. The results were 26 ± 4% [16]; 25.3 to 48.6% [46]; 36.2% [47]; 29.32% [30]; 44.9% [48]. Only [47] and [48] cited the values of a thousand Crambe seeds, which were 9.3 and 6.4 grams respectively, within the margin already seen in the literature [31].

Crambe Abyssinica oil production

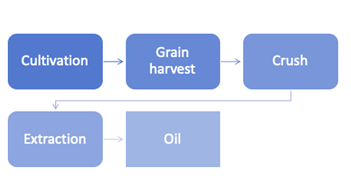

For the extraction of Crambe oil, some techniques can be used. These include pressurized liquid extraction, mechanical pressing, ultrasound-assisted extraction and soxhlet-assisted extraction. Pressurized liquid extraction occurs when a liquid solvent at high temperature increases the solubility of the oil, decreases the interaction of the matrix with the solvent, increasing the diffusion rate. In addition, high pressure is used so that the fluid density and boiling temperature remain high [31]. In mechanical pressing, the oil is extracted through the force exerted by a press, usually without the use of reagents, making this option a cheaper process, but with less efficiency [29]. In ultrasound-assisted extraction, high values of oil content are obtained from the biomass, using a low amount of solvent, occurring in a short period. In this type of extraction, the surface of the material is disrupted by the cavitation generated by the ultrasound, making the diffusion more accelerated [52]. The soxhlet is an extraction model often cited in the literature. An organic solvent is used on heating to extract the oil from the biomass [15]. The Crambe oil extraction process follows the flowchart 1.

Flowchart 1: Production of Crambe oil.

The amount of oil extracted can vary between 25 and 51%. This variation depends on some factors such as soil type, volume of water in irrigation, use of fertilizers, among other factors. Crambe oil can be used for various purposes, for example in the production of biodiesel [15]. It is worth mentioning that not only the oil, but all the biomass itself is used in Crambe, adding value to the biomass. In industry, in addition to biofuels, its seeds can also be used to produce adhesives, nylon, lubricants, electrical insulators, cosmetics, anticorrosive agents, rubbers, and its leaves can be used to produce nematicides [33].

Chemical composition and physical-chemical properties of Crambe oil

There is no significant change in the percentages of fatty acids in Crambe oil from one job to the next. The average fatty acid composition of Crambe oil is shown in Table 3 [32]. Only when there is a specific study to increase the percentage of one acid or another is there variation. In view of this, [34] used the protein Lipase A Moesziomyces Antarcticus (CAL-A) in order to enrich erucic acid from ethyl esters of Crambe oil. In this study, CAL-A variants are able to provide an oil with up to 80% erucic acid.

|

Fatty Acid |

Mass composition (%) |

|

Palmitic |

1.49 ± 0.01 |

|

Palmitoleic |

0.06 ± 0.04 |

|

Stearic |

0.71 ± 0.05 |

|

Oleic |

20.24 ± 0.18 |

|

linoleic |

5.80 ± 0.09 |

|

linolenic |

0.68 ± 0.07 |

|

Arachidic |

3.33 ± 0.09 |

|

Gadoleic |

5.62 ± 0.15 |

|

Behenic |

1.00 ± 0.07 |

|

Erucic |

59.94 ± 0.65 |

|

Lignoceric |

0.96 ± 0.01 |

|

Not Identified |

0.33 ± 0.02 |

|

Source: Adapted from [32]. |

|

Table 3: Composition of abyssinic crambe oil extracted by soxhlet with n-hexane.

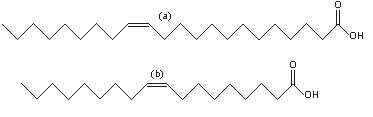

The fatty acids present in Crambe oil in the highest concentration are erucic acid (approximately 60%) and oleic acid (approximately 20%). The structures of the main acids are shown in figure 1.

Figure 1: Structure of erucic acid (a) and oleic acid (b).

The structure of Erucic Acid contains 22 carbons. At the 13th atom there is a double bond with CIS-type isomerism [34]. Oleic acid contains 18 carbon atoms, presenting a double with CIS conformation of the 9th carbon [53]. The presence of erucic acid in Crambe oil makes it unfit for human consumption. It is a toxic acid that can attack the heart directly in the myocardium with the accumulation of triglycerides, (TAG) [32]. This is due to the presence of tocopherols, which stand out in capturing free radicals as their main biological activity. The oil has a high oxidative stability, an important parameter when choosing a biomass for the production of biofuels [23].

Crambe oil as raw material for biodiesel production

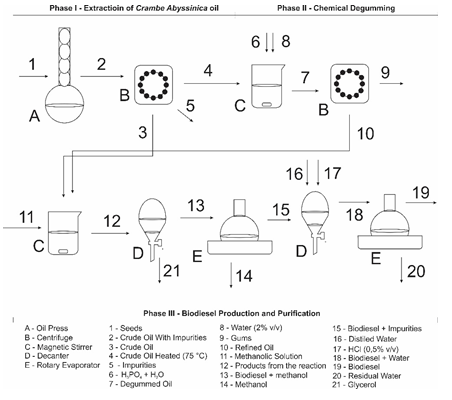

Some biomass conversion processes into biodiesel are already used in the literature. Such as hydroesterification [54], esterification [55], interesterification [56] and transesterification, usually the most used in research and industry. It is a process in which a triglyceride reacts with a short-chain alcohol (methanol or ethanol) in the presence of an acidic, basic or enzymatic catalyst producing, in addition to biodiesel, glycerol [35]. In figure 2, a flowchart with one of the possibilities of production and purification of biodiesel through degumming through Crambe seeds.

Figure 2: Biodiesel production and purification.

Source: Adapted from [16]

After biodiesel production, some parameters must be analyzed in order to consider the biomass to produce the biofuel to be mixed with diesel. This is the only way to know if biomass is a promising raw material or not for large-scale biodiesel production [37]. Viscosity, density, acidity and oxidative stability are among these parameters [16]. Several studies have already shown that the oxidative stability of biodiesel from Crambe is high, reaching 13 hours in some cases. With the characteristics of the literature, biodiesel from crambe is credible to be used as a mixture with fossil diesel sold at service stations or in a mixture with soy biodiesel (main raw material used for the production of biodiesel in Brazil) to mainly improve the oxidative and stability [37]. In Brazil, who regulates the specifications is the National Agency of Petroleum, Natural Gas and Biofuels (ANP) [36], while in Europe it is the EN 14214 - European Biodiesel Quality Standard [16].

Advanced alternative fuels and other products from Crambe

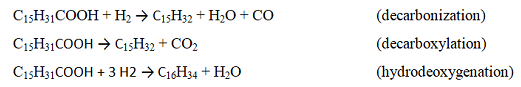

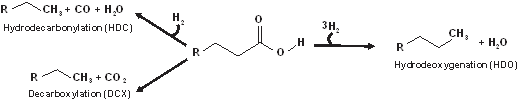

In addition to biodiesel, other types of biofuels have been studied recently, such as drop-in biofuels. These biofuels are liquid hydrocarbons with the amount of carbon chemically equivalent to their fossil analogues and with similar physicochemical properties, however, derived from renewable sources [26]. Among the Drop-in biofuels are Biokerosene, which is a biofuel that is in the carbon range of petroleum kerosene (C9 - C16), and green diesel that is in the carbon range of diesel derived from petroleum (C15 – C21) [11]. Due to the scarcity of works related to the use of Crambe oil for the production of Drop-in biofuels, this reinforces the need for studies to analyze the production and quality of these biofuels through this promising biomass. For the production of drop-in biofuels, in general, vegetable oil can be used as a raw material through deoxygenation, hydrogenation and hydrogenolysis processes. By deoxygenation, triglycerides can go through three pathways, decarbonylation, decarboxylation and hydrodeoxygenation. The three equations can be seen below [38].

Another process for converting biomass into drop-in fuels is hydroprocessing. It is the conversion of liquid biomass into drop-in biofuels where oxygen compounds are eliminated in the form of H2O, CO2 or CO through a hydrogenation reaction under controlled pressure and in the presence of a catalyst [39]. Figure 3 shows the elimination of oxygen during catalytic hydroprocessing.

Figure 3: Deoxygenation of fatty acids during the catalytic hydroprocessing.

In addition to raw material for the production of biofuels, biomass crambe abyssinica hochst is used to form several other products. To obtain a base for lubricating oil with adequate viscosity and properties [41], Crambe bran can be used in chicken feed to replace soybean bran [43], the concentration in Crambe protein can be used to feed fish [44], among others.

Conclusion

Consumption of fossil fuels, particularly for the transport sector, continues to increase worldwide. However, the aviation sector is increasingly investing in more energy efficient aircraft and in the production of aviation biofuels in order to mitigate GHG emissions caused by the burning of fossil fuels. The biomass Crambe abyssinica Hochst, originating from the Mediterranean, has good agronomic properties, adapts to different types of soil and water conditions. It presents resistance to pests and weeds and provides an oil with appropriate parameters for biodiesel production. Additional research is needed to verify the quality of drop-in biofuels produced from Crambe oil. Biodiesel from this raw material has already shown to be of good quality and promising for its use in the Brazilian energy matrix.

Acknowledgements

The authors thank the research facilities of the Federal University of Rio Grande do Norte (UFRN), as well as the Institute of Chemistry and the Graduate Program in Chemistry.

This research has not received any specific grant from funding agencies in the public, commercial or non-profit sectors.

References

- Yücenur G Nilay, Çaylak Seyma, Gönül Gözde, et al. an Integrated Solution with Swara&Copras Methods In Renewable Energy Production: City Selection For Biogas Facility. Renewable Energy 145 (2020): 2587-2597.

- BRASIL ANDRÉ OSÓRIO. (org.). BOLETIM MENSAL DE ENERGIA.

- RAVIGNÉ E, COSTA P, da. Economic and environmental performances of natural gas for heavy trucks: a case study on the french automotive industry supply chain. Energy Policy 149 (2021): 112019-112032.

- Slimane Faten Ben, Rousseau Antoine. Crowdlending Campaigns for Renewable Energy: Success Factors. : Success Factors. Journal Of Cleaner Production 249 (2020): 119330-119343.

- Stolarski Mariusz J, Krzysaniak Michal, Kwiatkowski Jacek, et al. Energy And Economic Efficiency Of Camelina And Crambe Biomass Production On A Large-Scale Farm In North-Eastern Poland. Energy 150 (2018): 770-780.

- Kiliçarslan Zerrin. The Relationship between Foreign Direct Investment and Renewable Energy Production: Evidence from Brazil, Russia, India, China, South Africa and Turkey. : Evidence from Brazil, Russia, India, China, South Africa and Turkey. International Journal of Energy Economics and Policy 9 (2019): 291-297.

- Stephenson AL, Dennis JS, Scott SA. Improving the Sustainability Of The Production Of Biodiesel From Oilseed Rape In The Uk. Process Safety And Environmental Protection 86 (2008): 427-440.

- LIMA Ma, MENDES Lfr, MOTHÉ Ga, et al. Renewable energy in reducing greenhouse gas emissions: reaching the goals of the paris agreement in brazil: Reaching the goals of the Paris agreement in Brazil. Environmental Development 33 (2020): 100504-100517.

- BRANCO José Eduardo Holler, BRANCO Daniela Holler, AGUIAR Edson Martins de, et al. Study of optimal locations for new sugarcane mills in Brazil: application of a minlp network equilibrium model. : Application of a MINLP network equilibrium model. Biomass And Bioenergy 127 (2019): 105249-105256.

- DEBONI Tamires Liza, SIMIONI Flávio José, BRAND Martha Andreia. LOPES, Gisele Paim. Evolution of the quality of forest biomass for energy generation in a cogeneration plant. Renewable Energy 135 (2019): 1291-1302.

- Souza Lorena Mendes De, Mendes Pietro AS, Aranda Donato AG. Oleaginous Feedstocks For Hydro-Processed Esters And Fatty Acids (Hefa) Biojet Production In Southeastern Brazil: A Multi-Criteria Decision Analysis. : A Multi-Criteria Decision Analysis. Renewable Energy 149 (2020): 1339-1351.

- ASIKIN-MIJAN N, OOI JM, ABDULKAREEM-ALSULTAN G, et al. Free-H2 deoxygenation of Jatropha curcas oil into cleaner diesel-grade biofuel over coconut residue-derived activated carbon catalyst. Journal Of Cleaner Production 249 (2020): 119381-119396.

- OROZCO Laura M, ECHEVERRI David A, SÁNCHEZ Lorena, et al. Second-generation green diesel from castor oil: development of a new and efficient continuous-production process. : Development of a new and efficient continuous-production process. Chemical Engineering Journal 322 (2017): 149-156.

- JIN Wenbin, XU Yan, YU Xiao-wei. Formation lipase cross-linked enzyme aggregates on octyl-modified mesocellular foams with oxidized sodium alginate. Colloids And Surfaces B: Biointerfaces 184 (2019): 110501-110508.

- COSTA E, ALMEIDA MF, ALVIM-FERRAZ C, et al. Cultivation of Crambe abyssinica non-food crop in Portugal for bioenergy purposes: agronomic and environmental assessment. : agronomic and environmental assessment. Industrial Crops and Products 139 (2019): 111501-111506.

- COSTA E, ALMEIDA Mf, ALVIM-FERRAZ C, et al. The cycle of biodiesel production from Crambe abyssinica in Portugal. Industrial Crops and Products 129 (2019): 51-58.

- LANDWEHR Katherine R, HILLAS Jessica, MEAD-HUNTER Ryan, et al. Soy Biodiesel Exhaust is More Toxic than Mineral Diesel Exhaust in Primary Human Airway Epithelial Cells. Environmental Science & Technology 53 (2019): 11437-11446.

- Saravanan A, Murugan M, Reddy M. Sreenivasa, et al. Performance And Emission Characteristics Of Variable Compression Ratio Ci Engine Fueled With Dual Biodiesel Blends Of Rapeseed And Mahua. Fuel 263 (2020): 116751-116758.

- CHONG Cheng Tung, CHIONG Meng-choung, NG Jo-han, et al. Oxygenated sunflower biodiesel: spectroscopic and emissions quantification under reacting swirl spray conditions. : Spectroscopic and emissions quantification under reacting swirl spray conditions. Energy 178 (2019): 804-813.

- DEMARINI David M, MUTLU Esra, WARREN Sarah H, et al. Mutagenicity emission factors of canola oil and waste vegetable oil biodiesel: comparison to soy biodiesel. : Comparison to soy biodiesel. Mutation Research/genetic Toxicology And Environmental Mutagenesis 846 (2019): 403057-403065.

- BUCHORI Luqman, ISTADI Istadi, PURWANTO Purwanto. Advanced Chemical Reactor Technologies for Biodiesel Production from Vegetable Oils - A Review. Bulletin of Chemical Reaction Engineering & Catalysis 11 (2016): 406-431.

- MOTA Francisco AS, COSTA FILHO JT, BARRETO GA. The Nile tilapia viscera oil extraction for biodiesel production in Brazil: an economic analysis. : An economic analysis. Renewable And Sustainable Energy Reviews 108 (2019): 1-10.

- BOSCHEN Nayara Lais, VALENGA Marcia Gabriela P, MAIA Guilherme AR, et al. Synergistic study of the antioxidant potential of barley waste for biodiesel. Industrial Crops and Products 140 (2019): 111624-111631.

- ANDRADE, Juliana (ed.). Mistura de biodiesel ao diesel passa a ser de 12% a partir de abril: medida vai elevar em 2 centavos preço para o consumidor. Medida vai elevar em 2 centavos preço para o consumidor. 2023. Disponível em: https://agenciabrasil.ebc.com.br/economia/noticia/2023-03/mistura-de-biodiesel-ao-diesel-passa-ser-de-12-partir-de-abril#:~:text=O%20Conselho%20Nacional%20de%20Pol%C3%ADtica,esse%20percentual%20%C3%A9%20de%2010%25.. Acesso em: 14 abr. 2023.

- Sousa Fabiana Pereira De, Produção De Biodiesel, et al. 2016. 175 F. Tese (Doutorado) - Curso De Química, Departamento De Química, Universidade Federal De Minas Gerais, Belo Horizonte (2016).

- MOREIRA Júlia de Barros Dias, REZENDE Daniel Bastos de, PASA Vânya Márcia Duarte. Deoxygenation of Macauba acid oil over Co-based catalyst supported on activated biochar from Macauba endocarp: a potential and sustainable route for green diesel and biokerosene production. : A potential and sustainable route for green diesel and biokerosene production. Fuel 269 (2020): 117253-117265.

- BUFFON Edervaldo, STRADIOTTO Nelson Ramos. Electrochemical behavior of hexahydrofarnesol: a contaminant of aviation biokerosene. : A contaminant of aviation biokerosene. Journal Of Electroanalytical Chemistry 848 (2019): 113284-113290.

- DELFINO José R, SILVA José Luiz da, MARQUES, Aldaléa Lb, et al. Antioxidants detection in aviation biokerosene by high-performance liquid chromatography using gold nanoparticles anchored in reduced graphene oxide. Fuel 260 (2020): 116315-116324.

- COSTA Emanuel, ALMEIDA Manuel Fonseca, ALVIM-FERRAZ Maria da Conceição, et al. Effect of Crambe abyssinica oil degumming in phosphorus concentration of refined oil and derived biodiesel. Renewable Energy 124 (2018): 27-33.

- MARINS Araceli Ciotti de, REICHERT José Miguel, SECCO Deonir, et al. Crambe grain yield and oil content affected by spatial variability in soil physical properties. Renewable And Sustainable Energy Reviews 81 (2018): 464-472.

- MELLO Bruna Tais Ferreira de, IWASSA Isabela Julio, CUCO Roberta Pazinato, et al. Methyl acetate as solvent in pressurized liquid extraction of crambe seed oil. The Journal Of Supercritical Fluids 145 (2019): 66-73.

- Trentini Caroline Portilho, Mello Bruna Tais Ferreira De, Cabral Vladimir Ferreira, et al. Crambe Seed Oil: Extraction And Reaction With Dimethyl Carbonate Under Pressurized Conditions. : Extraction And Reaction With Dimethyl Carbonate Under Pressurized Conditions. The Journal Of Supercritical Fluids 159 (2020): 104780-104789.

- SILVA Martha Freire da, ARAðJO Eduardo Fontes, SILVA Laércio Junio da, et al. Tolerance of crambe (Crambe abyssinica Hochst) to salinity and water stress during seed germination and initial seedling growth. Ciência e Agrotecnologia 43 (2019): 0-13.

- Zorn Katja, Oroz-Guinea Isabel, Bornscheuer Uwe T. Strategies For Enriching Erucic Acid From Crambe Abyssinica Oil By Improved Candida Antarctica Lipase A Variants. Process Biochemistry 79 (2019): 65-73.

- AGHEL Babak, MOHADESI Majid, ANSARI Ahmadreza, et al. Pilot-scale production of biodiesel from waste cooking oil using kettle limescale as a heterogeneous catalyst. Renewable Energy 142 (2019): 207-214.

- JOÃO CARLOS DE SOUZA MACHADO. (ed.). Anuário Estatístico Brasileiro do Petróleo, Gás Natural e Biocombustíveis. Rio de Janeiro - Rj - Brsil: Agência Nacional do Petróleo, Gás Natural e Biocombustíveis - Anp (2019): 264.

- Wazilewski Willian Tenfen, Bariccatti Reinaldo Aparecido, Martins Gislaine Iastiaque, et al. Study of The Methyl Crambe (Crambe Abyssinica Hochst) And Soybean Biodiesel Oxidative Stability. Industrial Crops and Products 43 (2013): 207-212.

- HONGLOI Nitchakul, PRAPAINAINAR Paweena, SEUBSAI Anusorn, et al. Nickel catalyst with different supports for green diesel production. Energy 182 (2019): 306-320.

- JEONG Hwiram, SHIN Mi, JEONG Byunghun, et al. Comparison of activity and stability of supported Ni2P and Pt catalysts in the hydroprocessing of palm oil into normal paraffins. Journal Of Industrial And Engineering Chemistry 83 (2020): 189-199.

- BAHARUDIN Khairul Basyar, ARUMUGAM Mahashanon, HUNNS James, et al. Octanoic acid hydrodeoxygenation over bifunctional Ni/Al-SBA-15 catalysts. Catalysis Science & Technology 9 (2019): 6673-6680.

- IlOWSKA Jolanta, CHROBAK Justyna, GRABOWSKI Rafal, et al. Designing Lubricating Properties of Vegetable Base Oils. Molecules 23 (2018): 2025-2036.

- GÄLLSTEDT, Mikael; PETTERSSON, Henrik; JOHANSSON, Therese; NEWSON, William R.; JOHANSSON, Eva; HEDENQVIST, Mikael S.. Film Extrusion of Crambe abyssinica/Wheat Gluten Blends. Journal of Visualized Experiments 119 (2017): 1-6.

- Silva TR, Ferreira MW, Marques RR, et al. Desempenho De Frangos De Pescoço Pelado Alimentados Com Farelo De Crambe (Crambe Abyssinica Hochst). Boletim De Indústria Animal 75 (2018): 1-7.

- Lovatto Naglezi M, Goulart Fernanda R, Loureiro Bruno B, et al. Crambe (Crambe Abyssinica) and Sunflower (Helianthus Annuus) Protein Concentrates: Production Methods and Nutritional Properties for Use in Fish Feed. : Production Methods and Nutritional Properties for Use in Fish Feed. Anais Da Academia Brasileira De Ciências 89 (2017): 2495-2504.

- TRANFIELD, David; DENYER, David; SMART, Palminder. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. British Journal of Management, v. 14, n. 3, p. 207-222, 2003.

- ALVES José M, LEANDRO Wilson M, ALVES Cassia CF, et al. Crambe dry matter and yield under doses of phosphorus and base saturation in the Cerrado of Goiás. Revista Brasileira de Engenharia Agrícola e Ambiental 20 (2016): 421-426.

- Soratto Rogério Peres, Souza-Schlick Genivaldo David De, Fernandes Adalton Mazetti Souza, et al. Effect Of Fertilization At Sowing On Nutrition And Yield Of Crambe In Second Season. R. Bras. Ci. Solo, Itália (2013): 658-666.

- Zanetti Federica, Scordia Danilo, Vamerali Teofilo, et al. Crambe Abyssinica A Non-Food Crop With Potential For The Mediterranean Climate: Insights On Productive Performances And Root Growth. : Insights On Productive Performances And Root Growth. Industrial Crops and Products 90 (2016): 152-160.

- KUMAR Alok, BAG Manas Kumar, SINGH Ranbir, et al. Natural infection of croton yellow vein mosaic virus and its cognate betasatellite in germplasm of different Crambe spp in India. Virus Research 243 (2018): 60-64.

- Wang YP, Tang JS, Chu CQ, et al. A Preliminary Study On The Introduction And Cultivation Of Crambe Abyssinica In China, An Oil Plant For Industrial Uses. Industrial Crops And Products, China 12 (2000): 47-52.

- BOIAGO Nayara Parisoto, FORTES Andréa Maria Teixeira, COELHO Silvia Renata Machado, et al. Morphophysiological and nutritional characteristics of Crambe abyssinica Hochst under hydric restriction in different phenological stages. Acta Physiologiae Plantarum 40 (2018): 0-6.

- Tavares Gilmar Roberto, Massa Thainara Bovo, Gonçalves José Eduardo, et al. Assessment of Ultrasound-Assisted Extraction Of Crambe Seed Oil For Biodiesel Synthesis By In Situ Interesterification. Renewable Energy 111 (2017): 659-665.

- FONTANA Angelo, SPOLAORE Barbara, LAURETO Patrizia Polverino de. The biological activities of protein/oleic acid complexes reside in the fatty acid. Biochimica Et Biophysica Acta (bba) - Proteins And Proteomics 1834 (2013): 1125-1143.

- MOWLA Omid, KENNEDY Eric, STOCKENHUBER Michael. Mass transfer and kinetic study on BEA zeolite-catalysed oil hydroesterification. Renewable Energy 135 (2019): 417-425.

- Shu Qing, Zou Wenqiang, He Jiangfan, et al. Preparation Of The F−-So42-/Mwcnts Catalyst And Kinetic Studies Of The Biodiesel Production Via Esterification Reaction Of Oleic Acid And Methanol. Renewable Energy 135 (2019): 836-845.

- Simões SS, Ribeiro JS, Celante D, et al. Heterogeneous Catalyst Screening For Fatty Acid Methyl Esters Production Through Interesterification Reaction. Renewable Energy 146 (2020): 719-726.

Impact Factor: * 5.3

Impact Factor: * 5.3 Acceptance Rate: 75.63%

Acceptance Rate: 75.63%  Time to first decision: 10.4 days

Time to first decision: 10.4 days  Time from article received to acceptance: 2-3 weeks

Time from article received to acceptance: 2-3 weeks