Fuzzy Analysis of Sensory Attributes of Gluten Free Pasta Prepared From Brown Rice, Amaranth, Flaxseed Flours and Whey Protein Concentrates

Ganga Sahay Meena1*, Aastha Dewan2, Neelam Upadhyay3, Ruchika Barapatre4, Nitin Kumar5, Ashish Kumar Singh6, Rana JS7

1,3,5Dairy Technology Division, National Dairy Research Institute, Karnal, Haryana, India

2,4,6Department of Biotechnology, Deenbandhu Chhotu Ram University of Science and Technology, Sonepat, Haryana, India

7Food Engineering Division, National Institute of Food Technology Entrepreneurship and Management, Sonepat, Haryana, India

*Corresponding Author: Dr. Ganga Sahay Meena, Dairy Technology Division, National Dairy Research Institute Karnal, Haryana-132001, India

Received: 23 January 2019; Accepted: 01 February 2019; Published: 05 February 2019

Article Information

Citation: Ganga Sahay Meena, Aastha Dewan, Neelam Upadhyay, Ruchika Barapatre, Nitin Kumar, Ashish Kumar Singh, Rana JS. Fuzzy Analysis of Sensory Attributes of Gluten Free Pasta Prepared From Brown Rice, Amaranth, Flaxseed Flours and Whey Protein Concentrates. Journal of Food Science and Nutrition Research 2 (2019): 022-037.

DOI: 10.26502/jfsnr.2642-1100006

View / Download Pdf Share at FacebookAbstract

Pasta is a cereal based, ready to cook, staple food, known for its affordable price, easy cooking, preferable sensory appeal and better storage stability, but its popularity is now growing as a healthy food worldwide. It is generally made from durum wheat semolina. Pasta made from gluten containing cereals creates problem for celiac patients. Hence, current study was undertaken (i) to prepare gluten free pasta from optimized levels of brown rice, amaranth flour, flaxseed flour and whey protein concentrate (WPC-70) and, (ii) to compare sensorial quality of gluten free pasta vis-a-vis available market samples of pasta to avoid market failure using fuzzy logic soft computing tool. Sensory evaluation was performed by a trained panel of sixteen judges. ‘In general’ ranking of pasta samples and their quality attributes was determined in linguistic term as (in decreasing order): Sample 4 (very good)> Sample 2 (very good)>Sample 3 (good)>Sample 1 (satisfactory) and Texture (highly important)>Flavor (highly important)> Appearance (important)>Color (important), respectively. However, exact ranking of pasta samples was obtained on the basis of maximum similarity value through fuzzy logic as shown in descending order: Sample 4 ‘very good’> Sample 2 ‘very good’>Sample 1 ‘good’>Sample 3 ‘good’. Gluten free pasta meets consumer’s preference in terms of ‘good’ sensorial quality as revealed by fuzzy logic; contains higher dietary fibre, minerals and superior milk proteins than traditional pasta made from durum wheat. Therefore, it can be considered as a better and nutritional choice for celiac patients and general consumers.

Keywords

<p>Fuzzy logic, Gluten free pasta, Sensory evaluation, Similarity values</p>

Article Details

1. Introduction

Pasta is a cereal based, ready to cook comfort food, highly popular owing to its easy cooking, preferable sensory and nutritional attributes, affordable price, versatility and better storage stability. It contains a range of diverse shapes and sizes like spaghetti, noodles, vermicelli etc. [1]. Most preferably used raw material for the production of pasta is durum wheat semolina. It contains gluten protein that enables proper dough formation via efficient networking of the matrix due to essential viscoelastic behaviour, exhibited upon mixing with water and in further extrusion process that is also vital for the desired quality attributes of cooked pasta. Presence of higher proteins, carotenoid pigment and mixture of gliadin and glutenin (gluten protein fractions) in durum wheat offers typical yellow color and ‘al dente’ chew ability and elasticity to the pasta [2]. Moreover, production process, sensory attributes and nutritional characteristics of the conventional pasta produced from durum wheat semolina is now well-established worldwide. The change in lifestyle, income, food preferences and consciousness of the end users towards safe, nutrient rich healthy foods has increased the demands of pasta enriched with nutrients and functional attributes and also forced the researchers to develop its variants containing natural compounds like flaxseed [3, 4], cereal brans [5], plant proteins [6], green gram semolina [7], vegetables (carrot, spinach, tomato, and turnip) and pearl millet [1], groundnut meal and carrot [8], groundnut meal and capsicum juice [9], groundnut meal and beetroot [10] etc. Moreover, consumption of gluten containing foods made from wheat, rye or barley is a severe problem for the persons suffering with celiac disease. For such patients, gluten free products are being manufactured from cereals (rice, corn and sorghum), minor cereals (fonio, teff, millet and job’s tears) or pseudo-cereals (amaranth, buckwheat, quinoa) as reported by [11]. However, partial or complete substitution of semolina with such non-conventional flours results in compromise between nutrition enrichment and desired sensory attributes of pasta.

1.1 Necessity of sensory evaluation and significance fuzzy logic in consumer preference analysis

Sensory attributes of the food products plays a vital role towards their acceptance or rejection by the consumers during the course of sensory evaluation. Sensory evaluation is a tool employed to evoke, measure, analyze and interpret typical product attributes which can be perceived by human senses and also to curtail the possible influence of brand identity on the end user [12]. It plays significant role during acceptance or rejection of food stuffs [13]. Nowadays, healthy and safe foods with inbuilt comparison and choice options are fundamental to consumers [14] and without appropriate sensory analysis, there is a high risk of market failure [15]. Subjective sensory evaluation has imprecision, inaccuracy and uncertain repeatability [13]. Although number of statistical packages are used in sensory data analysis yet, analyzed data remains inefficient for accurate interpretations owing to existing imprecision in variables [16]. Further, such packages are unable to highlight the data pertaining to the strength and weakness of individual quality characteristics of specific product that may ultimately decide its acceptance or rejection [17]. Fuzzy logic is a well-established decision-making tool that performs important functions such as development, improvement and comparison of the new products with similar existing products and also identify the impact of a specific quality attribute on the final quality of the developed product [18]. A mathematical relation is developed between independent (e.g. color, texture, flavor, appearance etc) and dependent (e.g. acceptance, rejection, ranking, strong and weak attributes of food) variables using the linguistic variables (e.g. not satisfactory, poor, fair, satisfactory etc.) during the course of fuzzy modeling. Moreover, it was considered as an efficient tool to deal with the existing uncertainty, vagueness and imprecision, resulting from the complexity of human behavior [13, 16, 19-21]. Several researchers has used it to draw vital inferences concerning with acceptance, rejection, ranking and to determine the strong and weak quality attributes of different food formulations [13, 18, 21-24]. This study was undertaken (i) to manufacture gluten free pasta with optimized levels of brown rice, amaranth, flaxseed flours and whey protein concentrates and, (ii) to compare the sensory characteristics of the manufactured sample with the similar product available in market through fuzzy logic modeling as a technique of sensory evaluation.

2. Material and Methods

2.1 Procurement of raw material

Brown rice (brand name-Maharani), flaxseed and amaranth flour were procured from local market of Karnal, while whey protein concentrate-70 (WPC-70) was procured from Modern Dairies Pvt. Ltd. Karnal, Haryana, India. Brown rice was milled (Flour Mill-Jumbo Shree) and sieved to get particle size >72 mm, which were further steamed for 5 minutes. Flaxseed was ground using mixer and sieved to get flour particle <72 mm.

2.2 Preparation of gluten free pasta

Using brown rice flour as a base material, levels of amaranth flour (5-20%), flaxseed flour (5-20%) and WPC-70 (1-5%) were earlier optimized by [25] using response surface methodology. Gluten free pasta samples were manufactured using the optimized levels of these ingredients as 20.00% amaranth flour, 10.00% flaxseed flour and 3.00% WPC-70. For gluten free pasta preparation, brown rice, amaranth and flaxseed flours and WPC-70 powder were properly dry mixed using 20 mesh sieve. Blended dry ingredients were further mixed in extruder (Make: Pizzato CE, Model: A 13 FR1-90330 FR515, Italy) chamber with optimal amount of water (final dough moisture up to 40%) for 10 minutes for uniform distribution of water. This machine was equipped with single screw with constant 50 round per minute (RPM). The wet mixture aggregates were transferred to a metal extruder attached with pasta machine that was fitted with an adjustable die. The rotation speed of external knife was 12 RPM to cut the extrudates. Wet pasta was dried in a fluidized bed dryer (SMST, SM Scientech, Kolkata; Machine no. 58) at 80°C / 45 min to attain a moisture content ? 8 %. The resultant dried pasta samples obtained were packed in low density polyethylene (LDPE) bags. Gluten free pasta manufactured from the optimized levels of ingredients as mentioned above was marked as Sample 1 while, rice vermicelli, vermicelli manufactured from semolina and whole wheat flour (1:1) and marconi pasta made from durum wheat of the established brands were procured from the local market of Karnal, Haryana and marked as Sample 2, Sample 3 and Sample 4, respectively.

2.3 Cooking of pasta samples

Total 500 g of each pasta sample was poured into 5 liter boiling RO water followed by the addition of 2% salt and 10% oil of the weight of pasta, checked for proper cooking as per AACC method, (AACC, 1999) and drained for five minutes.

2.4 Sensory evaluation through fuzzy logic

Sensory evaluation of pasta samples was performed by a semi-trained panel of sixteen normal judges consisting faculty of Dairy Technology Division, ICAR-NDRI, Karnal. Initially judges were trained about typical sensory attributes of pasta; familiarized with the score sheet, its use and method of scoring. Around 40 g of each sample was served to judges at 25 ± 1°C, to evaluate its various quality attributes properly. During sensory evaluation, a tick mark (?) was given by the judges to the concerned fuzzy scale factor for each quality attributes of the pasta sample. Thus, the pasta samples were marked as “Not satisfactory, ” “Fair, ” “Medium, ” “Good” and “Excellent”. The set of sensory scores (data) thus obtained were analyzed employing Fuzzy Logic analysis as earlier used and reported for Kheer Mohan [6], Shrikhand [18], mango drinks [19], dahi powder [22] instant green tea powder [23], bread [26] and many other authors for different food products.

2.5 Fuzzy logic analysis of the sensory data

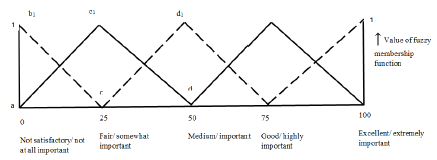

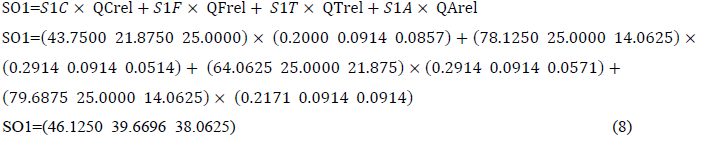

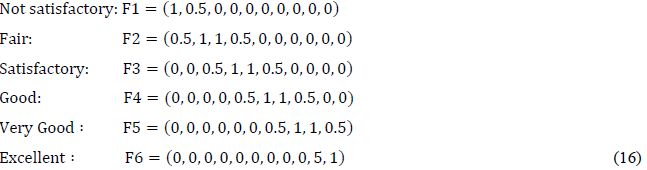

The sensorial scores obtained from the judges in the form of linguistic data is utilized in this method. A triangular fuzzy membership distribution function, as reported by [13] was used to rank the pasta samples. The linguistic data obtained from sensory panel was first converted to triplets (a set of three numbers) and then used to find out similarity values which were further used to determine the ranking of pasta samples. During fuzzy logic modeling of sensory data, the main steps involved as reported by [13] are the estimation of (1) overall sensory scores of pasta samples in the form of triplets; (2) membership function on standard fuzzy scale; (3) overall membership function on standard fuzzy scale; (4) similarity values and ranking of the pasta samples; as well as (5) in general ranking of the quality attribute of pasta samples. The numeric values of the triplets, general and overall membership function on standard fuzzy scale as well as similarity values of each pasta sample was calculated by developing a programme in in Matlab 12.1 (The MathWorks, McGarrity, 2008). The calculated triplet was used to represent triangular membership function distribution pattern of sensory scales. This distribution pattern of 5-point sensory scales consists of “Not satisfactory/Not at all important, (0, 0, 25)”, “Fair/ Somewhat important, (25, 25, 25),” “Medium/Important, (50, 25, 25)” “Good/Highly important (75, 25, 25)” and “Excellent/Extremely important (100, 25, 0)” as shown in Figure 1. Among the three numbers shown in the brackets of a triplet with 5-point sensory scales, first number depicts the coordinate of the abscissa having value of the membership function as 1 (Figure 1), while second and third numbers of this triplet shows the distance to the left and right side of the first number, where the membership function is zero [22].

Figure 1: Representation of triangular membership function distribution pattern of sensory scales.

3. Results and Discussion

3.1 Sensory evaluation by fuzzy logic modeling

The sum of sensory scores for the quality attributes and the sum of individual preference to quality attributes of pasta samples as given by the judges have been shown in Table 2 and Table 3. The analysis of sensory attributes of four pasta samples was further conducted using fuzzy logic adopting the procedure reported by [13]. It is evident from Table 2 that Sample 2 and Sample 4 had obtained better sensory acceptance for color, texture (gumminess, firmness, adhesiveness) and appearance (integrity, glossiness) while Sample 2 and Sample 3 obtained better flavour scores for over other pasta samples.

|

Poor |

Fair |

Good |

Very good |

Excellent |

|

0 0 25 |

25 25 25 |

50 25 25 |

75 25 25 |

100 25 0 |

Table 1: Triplets related with 5-point sensory scale.

|

Sensory quality characteristics |

Poor |

Fair |

Good |

Very Good (61-80) |

Excellent |

|

Color |

|||||

|

Sample 1 |

2 |

4 |

6 |

4 |

0 |

|

Sample 2 |

0 |

0 |

5 |

4 |

7 |

|

Sample 3 |

0 |

2 |

5 |

7 |

2 |

|

Sample 4 |

0 |

0 |

4 |

5 |

7 |

|

Flavor (taste, aroma) |

|||||

|

Sample 1 |

3 |

5 |

4 |

3 |

1 |

|

Sample 2 |

0 |

1 |

3 |

7 |

5 |

|

Sample 3 |

1 |

3 |

3 |

7 |

2 |

|

Sample 4 |

0 |

0 |

3 |

12 |

1 |

|

Texture (gumminess, firmness, adhesiveness) |

|||||

|

Sample 1 |

0 |

6 |

6 |

4 |

0 |

|

Sample 2 |

0 |

1 |

3 |

6 |

6 |

|

Sample 3 |

0 |

3 |

7 |

2 |

4 |

|

Sample 4 |

0 |

0 |

2 |

5 |

9 |

|

Appearance (integrity, glossiness) |

|||||

|

Sample 1 |

1 |

3 |

4 |

8 |

0 |

|

Sample 2 |

0 |

0 |

1 |

7 |

8 |

|

Sample 3 |

0 |

2 |

8 |

4 |

2 |

|

Sample 4 |

0 |

0 |

2 |

8 |

6 |

Table 2: Preference of sensory judges for specific quality attribute of pasta samples and triplets related with sensory scores.

3.2 Related triplets for the sensory scales for pasta samples

A set of three numbers i.e. ‘triplets’ were assigned for the triangular membership function distributions of sensory scales. The distribution pattern of five point sensory scales is: Not satisfactory/Not at all important (0, 0, 25), Fair/Somewhat important (25, 25, 25), Medium/Important (50, 25, 25), Good/Highly important (75, 25, 25) and Excellent/Extremely important (100, 25, 0) were the five point distribution pattern used for sensory scores. It is evident from Figure 1 that first number of triplet shows the value of membership function (1) on abscissa, while second and third numbers of this triplet showed the distance to its left and right having value as zero for the membership function.

3.3 Triplets for sensory quality of pasta samples

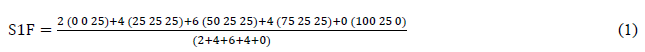

Triplet related to a quality characteristics of all pasta sample were obtained from their (a) sum of different sensory scores (Table 2); (b) concerned triplet (Table 1), and (c) the total number of judges (i.e. 16). This can be easily understand with the an suitable example i.e. to the color of sample 1, out of 16 judges; poor, fair, good, very good and excellent scores were given by two, four, six, four and zero judges respectively. Further, triplets concerned with the sensory scores of color of Sample 1were calculated as shown below:

Similarly, the values of other triplets of color (S1C), flavor (S1F), texture (S1T) and appearance (S1A) were calculated for Sample 1 as follows.

S1C=(43.7500 21.8750 25.0000)

S1F=(78.1250 25.0000 14.0625)

S1T=(64.0625 25.0000 21.875)

Similarly, for Sample 2 Sample 3 and Sample 4, values of triplets for flavor, texture and appearance were calculated and the same are shown below.

S2C=(40.6250 20.3125 23.4375)

S2F=(75.0000 25.0000 17.1875)

S2T=(59.3750 23.4375 21.8750)

S2A=(71.8750 25.0000 23.4375)

S3C=(46.8750 25.0000 25.0000)

S3F=(76.5625 25.0000 15.6250)

S3T=(60.9375 25.0000 18.7500)

S4A=(81.2500 25.0000 15.6250)

S4C=(54.6875 23.4375 25.000)

S4F=(85.9375 25.0000 12.5000)

S4T=(59.3750 25.0000 21.8750)

3.4 Triplets for judges’ preference to importance of quality attribute

Using sum of sensory scores (Table 3), (b) triplets associated with the sensory scales (Table 1) and (c) number of panelists (i.e. 16) the triplets of the individual preference to the significance of quality attributes of pasta in general were calculated. The value of the triplet QC for the first attribute i.e. color of pasta Sample 1 was computed as mentioned below.

=(54.6875 25.0000 23.4375)

Similar calculations were also done to get these values for other quality attributes i.e. for flavor, texture and appearance of pasta samples

QC=(54.6875 25.0000 23.4375)

QF=(79.6875 25.0000 14.0625)

QT=(79.6875 25.0000 15.6250)

|

Quality characteristics of pasta samples |

Sensory scale factors |

||||

|

NI-not at all important |

SI-somewhat important |

I-important |

HI-highly important |

EI-extremely important |

|

|

Color |

0 |

2 |

10 |

3 |

1 |

|

Flavor |

0 |

0 |

4 |

5 |

7 |

|

Texture |

0 |

2 |

6 |

8 |

0 |

|

Appearance |

0 |

0 |

3 |

7 |

6 |

Table 3: Total preference of sensory judges for specific quality attributes of pasta in general and the triplets related with those scores.

3.5 Overall sensory scores of pasta in triplets form

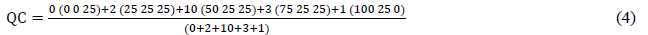

The overall sensory scores of a pasta sample were obtained as the sum of the product of the triplet earlier obtained through the equations 2 and 5. Using the following method, the product of triplet (a b c) with triplet (d e f) was calculated as mentioned below:

[3] reported that the value of the first digit of overall sensory score must be between 0 and 100 and the same was done by reducing the values in Equation 5 by a factor 1/Qsum (Qsum is the sum of first digit of the triplets). Moreover, relative weightage of the quality attributes for the sensory attributes of pasta were also defined as for

color: QCrel=QC/Qsum, flavor: QFrel=QF/Qsum, texture: QTrel=QT/Qsum and for appearnace: QArel=QS/Qsum. Thus, from Equation 5,

Qsum=54.6875+79.6875+79.6875+59.3750=273.4375

Triplet for relative weight for color QCrel was calculated as

QCrel=QC/Qsum

QCrel=(54.6875/273.4375, 25.0000/273.4375, 23.4375/273.4375)

=(0.2000 0.0914 0.0857)

Likewise, relative weightage of the other quality attributes i.e. flavour, texture and appearance were also calculated as mentioned below.

QCrel=(0.2000 0.0914 0.0857)

QFrel=(0.2914 0.0914 0.0514)

QTrel=(0.2914 0.0914 0.0571)

QArel=(0.2171 0.0914 0.0914)

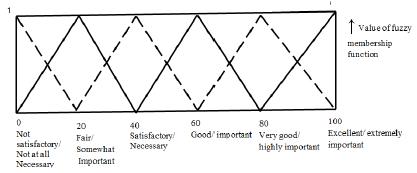

Adopting the rule of triplet multiplication as mentioned in Equation 6, overall sensory scores i.e. SO1 of sample 1 were calculated as mentioned hereunder.

Using the same procedure, overall sensory scores triplets of other pasta samples were calculated as shown below. It is indicative from Equation 8 that first digit of all triplets is <100.

SO1=(46.1250 39.6696 38. 0625)

SO2=(78.4554 53.8571 37.8750)

SO3=(60.7679 46.8304 38.4196)

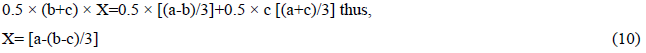

3.6 Standard fuzzy scale and ranking of pasta samples

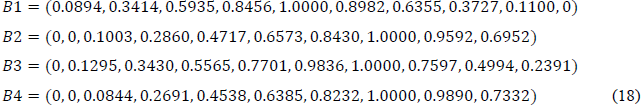

Standard fuzzy scale is a distribution pattern on 6-point sensory scale as depicted in Figure 2. The linguistic expressions such as Not satisfactory/Not at all necessary, Fair/somewhat necessary etc. to Excellent/Extremely important were set on standard fuzzy scale. It is evident from Figure 2 that a triangular distribution pattern was followed by the membership function (maximum value-1) for each sensorial score. Overall quality of pasta samples as denoted through a triplet (a, b, c) was linked to the standard fuzzy scale and shown by a triangle ABC in Figure 3.

Figure 2: Standard fuzzy scale.

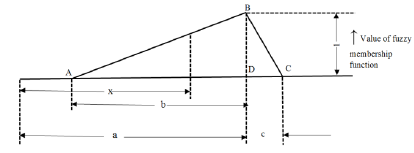

Initial digit of this triangle indicates towards the quality rating of pasta sample i.e. higher is the value, better is the quality and vice-versa. Further, ranking of any food stuff can be done by finding the location of the centroid of the triangle ABC, as depicted by the triplet (a, b, c) for the pasta sample. Moreover, both ABD and BDC are right angled triangles (Figure 3) and their centroid is located at the distance of 1/3 from their bases [13]. Area of triangles ABC, ABD and BDC will be 0.5 (b+c), 0.5b and 0.5c, respectively. Using these relations, the value of distance X (Figure 3) of the centroid of the triangle ABC can be calculated as mentioned below.

After getting the values of a, b, c triplets for overall quality attributes of each pasta samples from Equation 8 and placing them into Equation 9, the distance X for all samples were calculated and reported hereunder.

Xs1= 45.5893

Xs2=73.1280

Xs3=57.9643

As Xs4> Xs2> Xs3 >Xs1, so the noted order of ranking of pasta samples was sample 4> sample 2> sample 3> sample 1. Overall quality of pasta samples in linguistic terms was obtained by setting range for quality attributes such as not satisfactory: 0-10; fair: 11-30; satisfactory: 31-50; good: 50-70; very good: 71-90 and excellent: 91-100. By comparing the obtained values of X (Equation 11) with the set range of sensory scale, following ranking of pasta samples were observed in linguistic terms (similar to descriptive and 9-point hedonic scale method of sensory evaluation) without applying fuzzy logic analysis.

Sample 4> Sample 2> Sample 3> Sample 1

Sample 4 (very good)> Sample 2 (very good) > Sample 3 (good) > Sample 1 (satisfactory).

Figure 3: Graphical representation of overall sensory scores as triangle ABC and its triplet abc.

3.7 Ranking of the quality attributes of pasta samples in general

Ranking of the quality attributes of pasta samples in general was carried out adopting the same methodology earlier used for ranking of pasta samples. Triplets associated with the judjes’ liking towards importance of quality of pasta samples had been shown as triplets (a b c) in Equation 5, by placing these values back to Equation 10, the relative preference of quality attributes i.e. XQC, XQF, XQT and XQA of pasta samples in general were calculated as mentioned below.

XQC=54.1667

XQF=76.0417

XQT=76.5625

These values showed that texture of pasta sample was of prime importance and color was of the minimum importance. Thus, adopting the linguistic data ranges set for sensory scales between 0-100, the following in general ranking for quality attributes of pasta was obtained.

Texture (highly important)> Flavor (highly important)> Appearance (important)> Color (important)

3.8 Quality Attributes ranking of pasta samples

Adopting the similar procedure as used to determine the in general ranking of pasta samples and its attributes, relative contribution of color, flavour, texture and appearance on overall quality of pasta i.e. relative strengths and weakness of all pasta samples were also computed by comparing the individual triplets for overall sensory scores of quality attributes. The first digit of the product of two triplets was kept below 100 by increasing the values of QCrel, QFrel, QTrel and QArel (Equation 7) by a factor of 4. The overall sensory scores depicted C1 (color), F1 (flavour), T1 (texture) and A1 (appearance) of the sample 1 was given by

The numeric values of S1C, S1F, S1T, S1A and QCrel, QFrel, QTrel and QArel are given in Equations 2 and 7, respectively. Applying triplet multiplication rule (Equation 6), overall scores of C1 (color), F1 (flavour), T1 (texture) and A1 (appearance) were calculated as mentioned below.

C1=(35.0000 33.5000 35.0000)

F1=(47.3571 38.5357 35.6786)

T1=(54.6429 46.2857 39.8571)

Using these a, b, c values of the triplets (Equation 14) and placing them in Equation 10, the value of X for quality attributes of Sample 1 was calculated as

XC1=35.5000

XF1=46.4048

XT1=52.5000

Thus, the order of ranking for the quality attributes of Sample 1 was Sample 1: Texture (good)> Appearance (satisfactory) >Flavour (satisfactory)> Color (satisfactory). Moreover, it is clearly evident from Equation 15 that texture of Sample 1 was strongest while its color was the least important quality attribute. Similar calculations were also done to get the overall scores and X values for Sample 2, Sample 3 and Sample 4, respectively and their results are shown in Table 4 and Table 5. The order of ranking of quality attributes with their concerned sensory scale of remaining pasta samples are:

Sample 2: Texture (very good)> Flavour (very good)> Appearance (very good)> Color (good)

Sample 3: Texture (good)> Flavour (good)> Appearance (good)> Color (satisfactory)

Sample 4: Texture (excellent)> Flavour (very good)> Appearance (very good)> Color (good)

Attributes |

Sample 1 |

Sample 2 |

Sample 3 |

Sample 4 |

|

Overall scores |

||||

|

Color |

C1=(35.0000 33.5000 35.0000) |

C2=(62.5000 48.5714 38.0357) |

C3=(51.2500 43.4286 39.4643) |

C4=(63.7500 49.1429 38.5714) |

|

Flavour |

F1=(47.3571 38.5357 35.6786) |

F2=(87.4286 56.5714 35.4643) |

F3=(69.2143 49.0357 37.7143) |

F4=(83.7857 55.4286 42.1071) |

|

Texture |

T1=(54.6429 46.2857 39.8571) |

T2=(89.2500 57.1429 35.7143) |

T3=(71.0357 51.4286 35.7857) |

T4=(100.1786 60.5714 32.3929) |

|

Appearance |

A1=(47.5000 40.3571 41.7143) |

A2=(74.6429 53.1429 42.2857) |

A3=(51.5714 43.4286 40.7143) |

A4=(70.5714 51.4286 43.2857) |

Table 4: Finding the values of triplets for individual quality (color, flavor, texture, appearance) attributes of pasta samples.

|

Quality attributes |

Sample 1 |

Sample 2 |

Sample 3 |

Sample 4 |

|

Value of X for pasta samples |

||||

|

Color |

XC1=35.5000 |

XC2=58.9881 |

XC3=49.9286 |

XC4=60.2262 |

|

Flavour |

XF1=46.4048 |

XF2=80.3929 |

XF3=65.4405 |

XF4=79.3452 |

|

Texture |

XT1=52.5000 |

XT2=82.1071 |

XT4=65.8214 |

XT4=90.7857 |

|

Appearance |

XA1=47.9524 |

XA2=71.0238 |

XA3=50.6667 |

XA4=67.8571 |

Table 5: Determenation of the ranking of quality attributes of pasta samples.

3.9 Similarity analysis of pasta samples on standard fuzzy scale

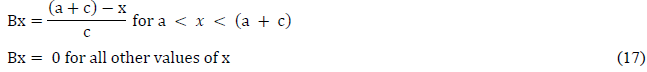

Overall sensory scores, obtained as a single triplet is distributed among six sensory scales of standard fuzzy scale using similarity analysis methodology. Pasta samples were ranked and designated in their respective sensory scores (linguistic form) by this method. Symbol F1 to F6 showed the six sensory scale from Not satisfactory/Not at all important to Excellent/ extremely important. Triangular distribution pattern was followed by the membership function of each sensory scale. All distributions have equal membership value as 1. Further, a set of 10 numbers, defined the values of membership function of F1 through F6 as “Maximum membership value of fuzzy membership function between 0 and 10 and such sequence was followed for ten sets up to 100.

From Figure 2, the values of membership function i.e. F1 (Not satisfactory/Not at all important), F2 (Fair/somewhat necessary), F3 (Satisfactory/necessary), F4 (Good/necessary), F5 (Very good/highly important) and F6 (Excellent/ extremely important) are

3.10 Determination of overall membership function of sensory scores on standard fuzzy logic scale

Values of the membership function of the overall sensory scores of pasta samples were find out on standard fuzzy scale using the values mentioned in Equation 9. The overall sensory scores of a particular triplet (a, b, c) as shown in Figure 4, indicates the value of membership function as 1 and 0 for the value of abscissa is either a or >(a + c) or <(a - c). Further, membership function value (Bx) as well as its triplet can be computed for a particular pasta sample considering x = 0 to 100 with an interval of 10 each on abscissa using Equation 5 [23].

Through the equation (17), values of Bx for all samples were obtained in the form of ten numbers set starting from “(maximum value of Bx at 0

Figure 4: Graphical representation of overall sensory scores as triplet (a b c) and its membership values.

3.11 Determination of Similarity values of pastasamples with their Ranking

For sample 1, sample 2, sample 3 and sample 4, the values of their membership functions has been shown in Equation 18 and compared with concerned values of the membership functions of standard fuzzy scale from Equation 16. Thereafter, the similarity values of all pasta samples under for F1-Not satisfactory, F2-Fair, F3-Satisfactory, F4-Good, F5-Very good, and F6-Excellent were calculated using the following Equation as reported by [18, 26, 27] and the obtained results has been shown in Table 6.

Highest similarity value of a particular pasta sample was considered to determine its quality i.e. higher is the similarity value, better is the quality and vice-versa. From columns 2, 3, 4 and 5 of Table 6, it is clear that for Sample 1, Sample 2, Sample 3 and Sample 4, the maximum similarity value falls under the category ‘good (0.7426)’, ‘very good (0.7067)’ ‘good (0.6512)’ and ‘very good (0.7120)’, respectively. So, the ranking of samples using maximum similarity value as criteria was as Sample 4> Sample 2> Sample 1> Sample 3. However, this ranking obtained after the application of fuzzy logic is different than the ‘in general’ ranking earlier observed for these pasta samples. [13] reported that exactness of the similarity method is greater than any other method. Here, it is clear that gluten free pasta prepared from the optimized levels of brown rice, amaranth flour, flaxseed flour and WPC-70 (sample 1) ranked under ‘good’ quality and better than market vermicelli manufactured using 1:1 ratio of semolina and whole wheat flour (sample 3). However, sample 1 was inferior in quality than market sample of marconi pasta made from durum wheat semolina (sample 4) and rice vermicelli (sample 2) because it is well-established that partial or complete substitution of semolina with non-conventional flours results in compromise between nutrition enrichment and desired sensory attributes of pasta. Therefore, during present investigation it was observed that gluten free pasta made from brown rice, amaranth flour, flaxseed flour and WPC-70 meets consumer’s sensory preference in terms of ‘good’ quality. Moreover, this gluten free pasta had higher dietary fibre, minerals and superior quality milk proteins than traditional pasta made from durum wheat and can be considered as a better nutritional choice for celiac patients in particular and other consumers in general.

|

Scale factors |

Similarity value for pasta samples |

|||

|

Sample 1 |

Sample 2 |

Sample 3 |

Sample 4 |

|

|

Not satisfactory, F0-10 |

0.0732 |

0 |

0.0166 |

0 |

|

Fair, F2 10-30 |

0.3947 |

0.0630 |

0.1931 |

0.0563 |

|

Satisfactory, F3 30-50 |

0.7293 |

0.2944 |

0.5118 |

0.2790 |

|

Good, F4 50-70 |

0.7426 |

0.4387 |

0.6512 |

0.4216 |

|

Very good, F5 70-90 |

0.2253 |

0.7067 |

0.4832 |

0.7120 |

|

Excellent, F6 90-100 |

0.0155 |

0.3043 |

0.1257 |

0.3159 |

|

Ranking of pasta samples |

III |

II |

IV |

I |

Table 6: Similarity values of pasta samples.

4. Conclusion

Sensory scores were obtained in linguistic form through the sensory evaluation, from a sensory panel of sixteen judges for manufactured (gluten free pasta) and similar pasta samples available in the market. In linguistic form, the noted ranking of pasta samples and its quality attributes were Sample 4 (very good)> Sample 2 (very good) > Sample 3 (good) > Sample 1 (satisfactory); Texture (highly important)> Flavor (highly important)> Appearance (important)> Color (important), respectively. The data was analyzed in its linguistic form applying fuzzy logic as soft computing tool and a method to evaluate and compare the sensory quality attributes of pasta samples. Results of fuzzy analysis showed that that based on similarity analysis the ranking of pasta samples were: Sample 4 > Sample 2> Sample 1> Sample 3 while texture and color were observed as highly important and important quality attributes of the pasta. Gluten free pasta sample prepared from the optimized levels of brown rice, amaranth flour, flaxseed flour and WPC-70 (sample 1) ranked under ‘good’ quality and considered better than market vermicelli (sample 3). Thus, it can be concluded that gluten free pasta manufactured using the optimized level of different ingredients (brown rice, amaranth flour, flaxseed flour and WPC-70) meets consumer’s preference in terms of ‘good’ sensorial quality as revealed by fuzzy logic and also contains higher dietary fibre, minerals and superior quality milk proteins than traditional pasta made from durum wheat. Therefore, it can be considered as a better and nutritional choice for celiac patients and general consumers.

Acknowledgement

First author sincerely acknowledge the faculty members of Dairy Technology Division, ICAR-National Dairy Research Institute, Karnal, Haryana India for their co-operation during the sensory evaluation of pasta samples. Thanks to the Director and Vice-Chancellor, Prof. Dr. Anil Kumar Srivastava for providing all the facilities to conduct this study.

References

- Yadav DN, Sharma M, Chikara N, et al. Quality Characteristics of Vegetable-Blended Wheat-Pearl Millet Composite Pasta. Agric Res 3 (2014): 263-270.

- Sozer N, Kaya A. The effect of cooking water composition on textural and cooking properties of spaghetti. Int J Food Prop 11 (2008): 351-362.

- Manthey FA, Sinha S, Wolf?Hall CE, et al. Effect of flaxseed flour and packaging on shelf life of refrigerated pasta. J Food Process Pres 32 (2008): 75-87.

- Sinha S, Manthey FA. Semolina and hydration level during extrusion affect quality of fresh pasta containing flaxseed flour. J Food Process Pres 32 (2008): 546-559.

- Kaur G, Sharma S, Nagi HPS, et al. Functional properties of pasta enriched with variable cereal brans. J Food Sci Technol 49 (2012): 467-474.

- Kaur G, Sharma S, Nagi HPS, et al. Enrichment of pasta with different plant proteins. J Food Sci Technol 50 (2013): 1000-1005.

- Jyotsna R, Sakhare SD, Inamdar AA, et al. Effect of Green Gram Semolina (Phaseolus aureus) on the Rheology, Nutrition, Microstructure and Quality Characteristics of High?Protein Pasta. J Food Process Pres 38 (2014): 1965-1972.

- Mridula D, Gupta RK, Khaira H, et al. Groundnut Meal and carrot fortified pasta: optimization of ingredients level using RSM. Proc Natl Acad Sci India Sect B Biol Sci. (2015).

- Mridula D, Gupta RK, Bhadwal S, et al. Optimization of Groundnut Meal and Capsicum Juice for Protein and Antioxidant Rich Pasta. Agric Res 5 (2016): 293-304.

- Mridula D, Gupta RK, Bhadwal S, et al. Optimization of food materials for development of nutritious pasta utilizing groundnut meal and beetroot. J Food Sci and Tech (2016): 1-11.

- Moreno Mdl, Comino I, Sousa C. Alternative Grains as Potential Raw Material for Gluten-Free Food. Development in the Diet of Celiac and Gluten-Sensitive Patients. Austin J Nutri Food Sci 2 (2014): 1-9.

- Stone H, Sidel JL. Sensory evaluation practices (3rd Edn.). California: Elsevier (2004).

- Das H. Food processing operations analysis (1st Edn.). New Delhi, India: Asian Books Private Limited (2005).

- Imm BY, Lee JH, Lee SH. Sensory quality index (SQI) for commercial food products. Food Qual Prefer 22 (2011): 135-139.

- Arazi S, Kilcast D. Leatherhead of food R.A. Food Processing Journal (2001): 21-22.

- Martinez L. Sensory evaluation based on linguistic decision analysis. Int J Approx Reason 44 (2007): 148-164.

- Lazim MA, Suriani M. Sensory evaluation of the selected coffee products using fuzzy approach. World Acad Sci Eng Technol 50 (2009): 717-720.

- Meena GS, Kumar N, Parmar PT, et al. Sensory Preference Modeling of Probiotic Shrikhand Employing Soft Computing. Agric Res 5 (2016): 362-372.

- Jaya S, Das H. Sensory evaluation of mango drinks using fuzzy logic. J Sens Stud 18 (2003): 163-176.

- Meena GS, Gupta VK, Khetra Y, et al. Fuzzy logic (Similarity Analysis) modelling for sensory evaluation of market samples of Kheer Mohan. Indian J Dairy Sci 68 (2015): 326-333.

- Mukhopadhyay S, Majumdar, GC, Goswami TK, et al. Fuzzy logic (similarity analysis) approach for sensory evaluation of chhana podo. LWT-Food Sci Technol 53 (2013): 204-210.

- Routary W, Mishra HN. Sensory evaluation of different drinks formulated from dahi (Indian yoghurt) powder using fuzzy logic. J Food Process Preserv 36 (2012): 1-10.

- Sinija VR, Mishra HN. Fuzzy analysis of sensory for quality evaluation and ranking of instant green tea powder and granules. Food Bioprocess Tech 4 (2011): 408-416.

- Uprit S, Mishra HN. Fuzzy multi-attribute decision making approach for development and comparison of soy fortified paneer. J Sens Stud 17 (2002): 163-176.

- Dewan A. Technology Development for the production and storage of gluten free pasta. Master Thesis, Deenbandhu Chotu Ram University of Science and Technology, Murthal, Haryana, India (2016).

- Singh KP, Mishra A, Mishra HN. Fuzzy analysis of sensory attributes of bread prepared from millet-based composite flours. LWT-Food Sci Technol 48 (2012): 276-282.

- Chen SM. A new approach to handling fuzzy decision making. IEEE Trans Syst Man Cybern 18 (1988): 1012-1016.

Impact Factor: * 3.8

Impact Factor: * 3.8 Acceptance Rate: 77.96%

Acceptance Rate: 77.96%  Time to first decision: 10.4 days

Time to first decision: 10.4 days  Time from article received to acceptance: 2-3 weeks

Time from article received to acceptance: 2-3 weeks