Study of Some Tribological Aspects in the Contact Area of A Friction Pair Operating with Selective Transfer

Filip Ilie1*, Andrei-Florin Hristache2

1Department of Machine Elements and Tribology, National University of Science and Technology POLITEHNICA Bucharest, Romania

2Department of Biotechnical Systems, National University of Science and Technology POLITEHNICA Bucharest, Romania

*Corresponding authors: Filip Ilie, Department of Machine Elements and Tribology, National University of Science and Technology POLITEHNICA Bucharest, Romania.

Received: 22 August 2025; Accepted: 28 August 2025; Published: 09 October 2025

Article Information

Citation: Filip Ilie, Andrei-Florin Hristache. Study of Some Tribological Aspects in the Contact Area of A Friction Pair Operating with Selective Transfer. Journal of Biotechnology and Biomedicine. 8 (2025): 322-327.

DOI: 10.26502/jbb.2642-91280199

View / Download Pdf Share at FacebookAbstract

The paper shows that under the conditions of selective transfer, there is a possibility for increasing the strain in the elements of the friction pairs without increasing their weight and size. The consequence is the increase in the actual contact surface and therefore the corresponding reduction of the actual pressure in the contact area, creating in this way the possibility for reducing friction and wear. Starting from these considerations, the paper presents some tribological aspects in the contact zone of a bronze/steel friction pair, which operates with selective transfer, based on the reduction of the real pressure in the contact zone.

Keywords

<p>Selective transfer; Real pressure reduction; Friction; Wear</p>

Article Details

Introduction

For research on friction pairs under conditions of selective transfer, experiments were conducted on friction pairs of copper alloys with steel, lubricated with glycerin, considering the methods of lubricant entry into contact areas and in the processes of mutual action.

This combination of materials was thus chosen because the elemental processes of this phenomenon can be explained by the special properties of glycerin [1-7]. Thus, the quantitative and qualitative transformations of the lubricant can be easily studied, even after frictional stress, as well as the deterioration of selective solution properties, metals, and alloys upon friction.

Experiments have confirmed that it is useful in the initial stage of friction to unfold thermodynamically unstable processes on the metallic surfaces of the friction pairs in contact, as well as in the lubricant. These are because in operating conditions, physicochemical processes favorable to friction take place, such as the formation of active substances, polymers, colloids, and other substances at the contact surface [8, 9].

The friction under such conditions is called selective transfer and is used where the duration of use of the friction pairs is not ensured, or the friction of the mixed and adhesion layers is not sufficiently safe [1-5].

The selective transfer is characterized by a complex of physic-chemical processes from the contact areas depending on the external conditions (pressure, sliding speed, temperature) and of a factors series that act on the processes (lubricant thermodynamic instability and of material, collisions between the friction surfaces asperities, or the catalytic effect of the oxide and metal layers on the lubricant, called tribodestruction).

The lubricant tribodestruction, at the beginning of friction, under the selective transfer conditions leads, both to the solution of the oxidation problem, and to a series of other processes favorable to friction (production of electrical charges, depolarization by friction, and emission of electrons, formation of metal-organic compounds, colloids, and surfactants) [1, 2, 10, 11]. All these have as effect, transporting metal particles in the contact area until the balance among these and the friction surface is established [9], forming a thin polymerized superficial layer, called also servovitte, and the reduction of friction and wear becomes possible with certainty.

It is the case of the bronze/steel friction pair, where take place the copper particle transfer on the steel surface cleaned of the oxide layer. It could therefore be established that the change in external conditions (load, speed, and temperature), which disrupts the balance between the contact area and the friction surfaces' area, where there is no contact, remains constant for the given operating conditions, and in this way, it certainly contributes to the reduction of friction and wear throughout the operation period.

Therefore, the aim of the work is to analyze some tribological aspects in the contact zone of the bronze/steel friction pair, which operates with selective transfer, regarding the reduction of the real pressure in the contact area.

Materials and Methods

For the experimental tests regarding the evaluation of some tribological aspects (of friction and wear) in the contact area of the friction pair elements (bronze/steel) in selective transfer conditions, the Timken tribometer was used.

The friction pair elements in the selective were a roller sample of bronze, CuSn12T (equivalent UNS-C90800), and a pill flat sample of steel, OLC 45 (equivalent AISI/SAE 1045), lubricated with glycerin, at speed of v = 0.98 m/s and the pressure in the contact area, p = 4 MPa, operating for 2 hours, lubricated with glycerin. In the research and experimental studies carried out under conditions of selective transfer, this lubricant was used because it achieves the selective transfer regime more easily than other lubricants.

The functional behavior of machines, installations, devices, etc., is dependent on operating parameters (load, speed, operating environment, etc.), as well as on the initial quality of the contact surfaces, which changes continuously, with a lower or higher speed [12-15]. The surface roughness, physical-mechanical condition, the superficial layer microstructure, and the permanent stresses caused by mechanical processing or the final heat treatment are properties that characterize the contact surface quality of the friction pairs [16,17]. An important role in the operation of pairs with friction and minimal wear, as in the case of friction pairs with selective transfer, is played by the arrangement of the asperities of the friction surfaces [18-20].

Therefore, specific to the selective transfer mechanism is the material transfer from one element of the friction pair to the other that manifests itself in the friction process of certain materials and the presence of suitable lubricants. This transfer takes place for a certain time, stabilizing at an optimal thickness, then the process occurs in reverse (the transferred layer in surplus returns to the initial element), surely leading to the improvement of the quality of the friction surfaces.

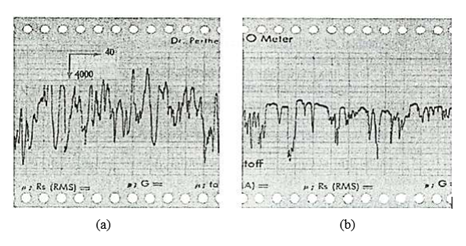

The analysis of the state of the surfaces of the pair bronze/steel was done with the help of a Perth O. Meter profilograph (Hirox Europe, Limonest, France) before as well as after the experiments, with the help of which the profilograms of the contact surfaces were drawn.

To confirm the presence of a thin polymerized superficial layer, and to understand various phenomena that occur during the selective transfer process, including surface reactions, material properties, and the effectiveness of surface layers, a JXA-5A electronic microprobe, JEOL Ltd., Tokyo, Japan, was used. Electronic microprobe utilizes surface-sensitive techniques that focus on the outermost layers of a material, providing detailed information on the chemical composition, electronic structure, and surface morphology.

The temperature measurement in the contact area of the bronze/steel pair samples during friction operation by selective transfer, on the Timken installation at different loads and sliding speeds, was done with a digital thermometer (Mestek IR02C-50 +800°C, SC Bitmi Technologies SRL, Falticeni, Suceava, Romania).

Additionally, to highlight the wear, a high-precision digital micrometer (0–25/0.0002 mm IP65 INSIZE Czech s.r.o, Ivančice, Czech Republic), respectively, an analytical balance (ACA620, 620 g/0.001 g, TELECOMED SRL, Valea Adanca, Iasi, Romania) was used.

Results and Discussion

Reduction of the real pressure in the contact area

In the selective transfer conditions, a possibility to reduce friction and wear is the pressure reduction in the contact area of the friction pairs. It is known that the real contact surface is about 10 - 100 times smaller than the nominal friction surface [1, 3, 21, 22], and if it is worn properly, it changes very little during the working process, because it is related to the mechanism of self-regulation and obtaining optimal roughness during operation [23, 24].

Along with the conditions that the lubricant must fulfill in real contact, the stress, the materials of the friction pairs, and many other factors have an influence.

During the operation of friction pairs, a large part of the friction surface is not used, which means that there is always a reserve.

In the contact areas, high real pressures arise, which act on the surface even at low nominal loads, which can lead to elastic and plastic deformations of certain areas. For this reason, to decrease the real contact pressure value, the nominal contact surface must be increased in many cases/situations [1, 2, 21-24], for example, in the case of a bearing. This is in contradiction to the requirement and effort of the designers to decrease the mass while simultaneously increasing its resistance.

The friction process under the conditions of a selective transfer takes place by the activation of electrochemical processes, with the dissolution of the anodic alloy elements at high voltages in the areas of the contact surfaces.

By dissolving the anodic components of the metal, surfactants are formed, which are adsorbed by the areas that play the role of cathodes. This reduces the resistance and favors the formation of colloidal particles. Surfactants and colloids are very good lubricants.

It is expected that when the real contact surface increases and when the stresses from the plastic deformation range (2000 - 3000 MPa) go to lower values, the process of increasing the surface will slow down. This is proven by the profilogram of the friction surface micro geometry in Figure 1, obtained with the help of the Perth O. Meter profilograph, on a specimen from the Timken-type friction pair (bronze/steel), in its initial state (Figure 1a) and after selective transfer (Figure 1b).

The difference between the initial state (resulting from mechanical processing, with varied and sharp shapes of the asperities of the friction surface) of the friction surface micro geometry and that after the selective transfer, where the friction surfaces asperities are much flattened (as if they are cut or as after running-in when an optimal roughness is obtained, respectively a "balance" surface [25]).

This is possible because the depressions/gaps between the asperities are filled with a thin layer (film) of copper, up to a certain level, corresponding to the optimal roughness, leading to the increase of the real contact surface and therefore to the decrease of the real contact pressure, having the effect of reducing friction and wear.

However, the common influence of the selective solution from structure components and the resistance reduction by adsorption, together with the rest of the cathode alloying components, leads to a dense layer formation of these components.

From the point of view of density, the layer is similar to a liquid, something proved by Kuksenova and Sevenko în ref. [26] and confirmed by Ilie in ref. [27].

The fact that this layer is in a special structural state also conditions its lubrication capacity. This makes it possible for the friction to take place under conditions of a much higher pressure than with the friction of mixed or adhesion layers [28].

Thus, with the help JXA-5A electronic microprobe in Figure 2 highlights the presence of the thin polymerized superficial layer (servowitte) in the friction areas. It can be observed that the layer microstructure in depth with the selective layer transferred and with a porous structure - 1 in which copper dominates (over 85%), interface 2 between the selective layer, and the structure of the base material (steel) - 3.

Impact of selective transfer on reducing the real contact pressure

Increasing the real contact surface and the corresponding reduction of the real load in the contact area are possibilities for reducing friction, and, implicitly, wear, respectively, growth the load-carrying capacity. At the same time as reducing the real contact pressure, a compensation of the forces acting on the friction surfaces is also obtained. This is necessary for the protection of the layer against breakage and its deformation during the friction process. The reduction of the real contact pressure is a result of the formation of the so-called servowitte (saving life) layer on the friction surfaces by the selective dissolution of a thin superficial layer. This layer is protected against destruction because it has the property of ensuring an agglomeration of dislocations to an extent similar to that of malleable materials, during deformation processes [1, 3]. In the presence of organic compounds and surfactants, this layer gives a friction coefficient value comparable to fluid friction, a layer that has a high density of point defects [2].

At the same time, the increase of the real contact surface to approximately the size of the nominal contact surface and the reduction of the friction coefficient, by more than ten times (as is typical for fluid friction) led to the assumption that friction does not take place between the solid areas of the surface, but between limited areas with very little interaction within these areas. Researching this state of the layers is difficult because it exists only in the friction process and only under conditions of very high pressure, at a well-established temperature, and only during the development of special tribotechnical processes. When the rubbing process is finished, this layer ceases to exist.

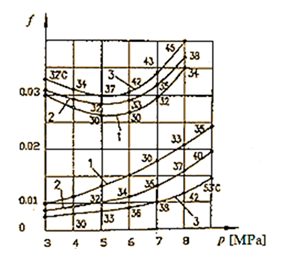

For example, Figure 3 shows the friction coefficient variation, f, depending on the pressure, p, for different sliding speeds, under friction conditions between the adherent layers (the upper curves) and under conditions of selective transfer (lower curves). On the curves are presented the average temperature values, which have resulted, in the values friction coefficients, f, corresponding to the given demands/pressures, p, and were determined experimentally on samples made of copper-based alloys (CuSn12T, equivalent to UNS-C90800) in contact with steel samples (OLC 45, equivalent to AISI/SAE 1045) [29] of the roller - flat pill type, on the Timken installation (tribometer).

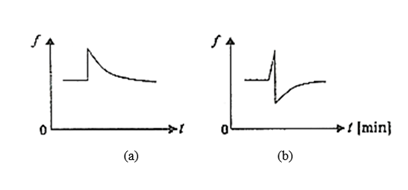

It is worth noting that during the friction of the adherent layers, the temperature increase determines that the friction coefficient increases, with the increase in speed, while in the selective transfer conditions, there is a reduction of the friction coefficient with the temperature increase. It is mentioned that the temperatures shown on the curves in Figure 3 were measured using a Mestek IR02C-50 digital thermometer. Therefore, the reactions that take place during the selective transfer cause an improvement in the lubrication and a reduction in the viscosity of this layer during the chemisorption processes. This is not possible in the usual friction between the adherent layers. Similar reactions also take place in conditions where high demands suddenly appear during the selective transfer. Figure 4 shows schematically the variation of the friction coefficient, f, depending on time, t, upon the sudden appearance of an additional stress in the friction conditions between adherent layers (Figure 4, a) and in the selective transfer conditions (Figure 4, b) [3, 5].

After removing the additional load, the friction coefficient value gradually returns to the initial value under the conditions of friction between the adherent layers, and under the selective transfer conditions, this decreases a lot, to gradually return to the initial value.

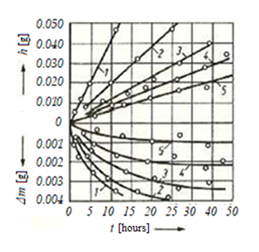

To estimate the wear under selective transfer conditions (which is very low), it was quantitatively established by measurement during experimental tests, collected by measuring the mass loss, Δm (in grams, by weighing), concurrently with the thickness of the worn layer, h (in mm), both for roller and for flat pill. The mass loss, Δm, in grams, was measured by weighing with the help of an analytical balance of 620 g/0.001 g, respectively, the average thickness of the worn layer, h, in grams, with a high-precision digital micrometer of 0–25/0.0002 mm.

The measurements were made every 15 min, within a 2-h interval (120 min), rotational speed, v = 0.98m/s, and the contact pressure of 4 MPa in well-established and marked points, considering as value the average of the values from these points.

In addition, wear research on the considered bronze/steel pair shows that the thickness of the transferred layer, h (expressed in g), on the steel contact surface increases, and the mass loss, Δm of the bronze (expressed in g), increases much faster, as the contact pressure increases, as shown in Figure 5.

It can be seen that the mass loss is very small (with the mention that, at the bronze specimen, it is comparatively higher compared to that of steel) and with a tendency to stabilize over time. This is possible until the equilibrium conditions are established in the contact area, then the process is reversed (the material transferred surplus on the steel sample returns to the bronze one.

The analysis of the results obtained on the bronze/steel friction pair shows the friction coefficient and wear normal evolution, but with very low values, which prove that in selective transfer conditions, friction and wear are minimal. These surely lead to an increase in the durability of the friction pairs when they are lubricated with glycerin and one of the pair elements is made of a copper-based alloy.

The increase in wear with the increase in contact pressure can be explained by the fact that the separated copper negative (cathode) particles have a weak adhesion on the bronze surface.

Conclusions

The selective transfer is a complex phenomenon that leads to the self-regulation of the imbalance in a friction pair, when wear occurs, as well as to a reduction of the frictional force. The complexity of the selective transfer phenomenon is highlighted by the reduction of the real pressure in the contact area, deformation compensation, and reduction of the sliding/shearing resistance in the superficial areas, return of the particles removed from the friction surfaces back in the contact area, and the formation of the polymerized protective layer (servowitte). The reduction of the real contact pressure as a result of the increase of the real contact surface to approximately the size of the nominal contact surface, and the reduction of the friction coefficient and wear led to the assumption that friction does not take place between solid areas of the surface, but between limited areas with very little interaction within them. Researching this state of the layers is difficult because it exists only in the friction process and only under conditions of very high pressure, at a well-established temperature, and only during the development of special tribotechnical processes. When the rubbing process is finished, this layer ceases to exist. In addition, researchers have shown that a reduction of the real contact pressure increases the friction pairs' safety, as well as their bearing capacity. Also, it can be stated that in the pairs operating under selective transfer conditions, the stresses on the components of a machine can be increased considerably, without increasing their mass and dimensions.

References

- Garkunov DN. Erhohunug der Verschleibfestigkeit auf der Grudlage der selektiven Ubertragung. UEB Verlag, Technik, Berlin, Germany. (1981).

- Ilie F. Tribological study of the thin superficial layers formed in the friction couples by selective transfer, Technical Publishing House, Bucharest, Romania. (2002).

- Garkunov DN. Triboengineering. Design, Production and Operation of Machines (in Russian), Izd. MSKhA, Moskau, Russia. (2002).

- Turis J, Beno P, Bialy W. The Optimal Tribotechnical Factors in the Design of Machines – Environmental Element in the Production Systems, Management Systems in Production Engineering 26 (2018): 207-211.

- Ilie F, Ipate G. A Modelling Study of the Correlation between the Layer Obtained by Selective Transfer and the Dislocations Movement at the Friction Surfaces Limit, Metals 12 (2022): 180.

- Yazawa S, Minami I, Prakash B. Reducing Friction and Wear of Tribological Systems through Hybrid Tribofilm Consisting of Coating and Lubricants, Lubricants 2 (2014): 90-112.

- Ilie F. Tribological behaviour of the steel/bronze friction pair (journal bearing type) functioning with selective mass transfer, International Journal of Heat and Mass Transfer 124 (2018): 655-662.

- Popov VL, Li Q, Lyashenko IA, et al. Adhesion and friction in hard and soft contacts: theory and experiment, Friction 9 (2021): 1688–1706.

- Parkatzidis K, Wang HS, Truong NP, et al. Recent Developments and Future Challenges in Controlled Radical Polymerization: A 2020 Update, Chem 6 (2020): 1575-1588.

- Chen X, Han Z, Li X, et al. Lowering coefficient of friction in Cu alloys with stable gradient nanostructures. Sci Adv 2 (2016): e1601942.

- Cao H, Zhou X, Li X, et al. Friction mechanism in the running-in stage of copper: From plastic deformation to delamination and oxidation. Tribol Int 115 (2017): 3–7.

- Kovalev A, Yazhao Z, Hui C, et al. A Concept of the Effective Surface Profile to Predict the Roughness Parameters of Worn Surface, Front. Mech. Eng., Sec. Tribology 5 (2019): 1-11.

- Rudzitis J, Bulaha N, Lungevics J, et al. Theoretical analysis of spacing parameters of anisotropic 3D surface roughness, Latvian Journal of Physics and Technical Sciences 54 (2017): 55-63.

- Rudzitis J. Mechanics of Surface Contact. Part 1. Parameters of Surface Roughness Profile. Riga: Riga Technical University (2007).

- Lu W, Zhang G, Liu X, et al. Prediction of surface topography at the end of sliding running-in wear based on areal surface parameters Tribol Trans 57 (2014): 553–560.

- LeeD-H, Cho N-G. Assessment of surface profile data acquired by a stylus profilometer. Meas Sci Technol 23 (2012): 105601.

- Wen Y, Tang J, Zhou W, et al. An improved simplified model of rough surface profile. Tribol Int 125 (2018): 75–84.

- Wen Y, Tang J, Zhou W, et al. New analytical model of elastic-plastic contact for three dimensional rough surfaces considering interaction of asperities, Friction 10 (2022): 217–231.

- Zhang W, Lu Z, Chen Y, et al. Contact analysis between rough surfaces considering the size-affected deformation behaviour of multi-scale asperities. Tribol Int 172 (2022): 107592.

- Xie W, Liu C, Huang G, et al. Nano-sized single-asperity friction behavior: Insight from molecular dynamics simulations. Eur. J. Mech.-A/Solids 96 (2022): 104760.

- Kraghelski IV. Reibung und Versleiss, VEB Verlag Tehnik, Berlin, Germany. (1971).

- Jeyaprakash N, Yang C-H. Chapter: Friction, Lubrication, and Wear, in book Tribology, Publisher: IntechOpen (2020).

- Tudor A. Real contact of friction surfaces (in Romanian), Romanian Academy Publishing House 1990, Bucharest, Romania.

- Sahli R, Pallares G, Ducottet C, et al. Evolution of real contact area under shear and the value of static friction of soft materials, Applied Physical Sciences 115 (2018): 471-476.

- Ilie F, Juganaru A, Ipate G. Study of the Condition of the Surfaces Covered by Selective Transfer for the Spindle-Bearing Friction Pair, J Math Techniques Comput Math 4 (2025): 01-10.

- Kuksenova L, Savenko V. Structural Changes and Diffusion in the Zone of Contact Deformation of Copper Alloys Under Friction, Metal Science and Heat Treatment 65 (2024).

- Ilie F. Study of Superficial Layers Obtained by Selective Transfer in the Friction Couples. European Journal of Engineering Research and Science 2 (2017): 54-54.

- Ilie F, Cotici CD, Hristache A-F. - A possibility of tribological investigation of physicochemical processes in a friction pair operating under selective transfer conditions, Lubricants 13 (2025): 331.

- *** Cast irons and steels. Standard (in Romanian), Technical Publishing House, Bucharest 1980, Romania.

Impact Factor: * 5.3

Impact Factor: * 5.3 Acceptance Rate: 75.63%

Acceptance Rate: 75.63%  Time to first decision: 10.4 days

Time to first decision: 10.4 days  Time from article received to acceptance: 2-3 weeks

Time from article received to acceptance: 2-3 weeks